Best 10 Jig Saw Blades for Metal Cutting in 2023

Table of Contents

- Top Features to Look for in Jigsaw Blades for Metal Cutting

- Material Types of Jigsaw Blades Suitable for Metal Cutting

- Understanding Tooth Geometry for Optimal Metal Cutting Performance

- Comparison of Bi-Metal vs. High-Speed Steel Jigsaw Blades

- Best Brands for Metal Cutting Jigsaw Blades in 2023

- User Reviews and Ratings of Popular Jigsaw Blades for Metal

- Maintenance Tips for Prolonging the Life of Jigsaw Blades

- A Comprehensive Guide to Choosing and Using T118A Metal Cutting Jigsaw Blades for Precision Work

- FAQS

- Conclusion

- Related Posts

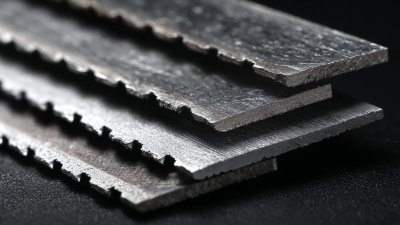

In the ever-changing world of metalworking, choosing the right tools can seriously make or break the quality and speed of your project. Among all the options out there, Jig Saw Blades for metal have really become a go-to for both pros working in factories and DIY folks working on their weekend projects. Based on the latest industry report from Market Research Future, the demand for top-notch Jig Saw Blades Metal is expected to grow at about 5.8% per year until 2027. That’s a pretty clear sign of just how crucial these cutting tools are—especially in industries like automotive, aerospace, and construction.

Dr. Emily Harrington, who’s a pretty big name in cutting tech at the Institute of Advanced Manufacturing, sums it up well: choosing the right metal blade isn’t just about getting the cut right—it also helps your tools last longer, which saves you money in the long run. As metalworking gets more complex and challenging, it’s more important than ever to understand what makes different blades tick—like the materials they’re made of, the shape of their teeth, and the best ways to use them.

This article is all about the top 10 Jig Saw Blades for metal in 2023. We’ll go over their key features and where they’re best suited so you can pick the best one for your needs. By knowing what’s out there, you’ll be able to work smarter, boost your productivity, and get that professional finish every time.

Top Features to Look for in Jigsaw Blades for Metal Cutting

When choosing jigsaw blades for metal cutting, several key features should be considered to ensure optimal performance and precision. First and foremost, the type of tooth design plays a crucial role.

Blades with carbide or high-speed steel tips are often preferred, as they provide durability and the ability to cut through various metal thicknesses cleanly. Additionally, a finer tooth pitch is advantageous for intricate or detailed cuts, while a coarser pitch is better for faster, more aggressive cuts.

Another important aspect to consider is the blade thickness and width. Thicker blades tend to provide increased stability, reducing vibrations during the cutting process, which can lead to cleaner cuts. Furthermore, the overall length of the jigsaw blade should align with the specific metal materials being cut; longer blades can accommodate deeper cuts in thicker materials. Lastly, it's essential to ensure that the blades are compatible with the jigsaw model, as this affects the ease of installation and functionality during use.

Selecting blades with the right combination of these features will ensure successful metal cutting projects in 2023.

Material Types of Jigsaw Blades Suitable for Metal Cutting

When it comes to cutting metal with a jigsaw, selecting the right blade material is crucial for both performance and durability. The most common materials used for jigsaw blades suitable for metal cutting include high-carbon steel (HCS), high-speed steel (HSS), bi-metal, and carbide. Each material offers distinct advantages. High-speed steel blades, for example, are known for their robustness and ability to withstand heat, making them ideal for cutting through tougher metals. According to a report by the International Journal of Advanced Manufacturing Technology, blades made of HSS can maintain their cutting edge up to 30% longer than traditional high-carbon steel blades, significantly enhancing efficiency during metal fabrication projects.

Bi-metal blades, which combine the flexibility of high-carbon steel with the cutting efficiency of high-speed steel, are increasingly recognized for their ability to cut through a wider range of metal types without breaking. Research from the Metalworking Industry Association indicates that bi-metal blades account for over 60% of jigsaw blade sales in the metalworking sector due to their superior performance in heavy-duty applications. Additionally, carbide-tipped blades are engineered for cutting hard metals and materials with extreme precision, allowing for intricate designs that are often required in modern manufacturing and HVAC installations. This diversified range of materials ensures that professionals can select the right jigsaw blade tailored to their specific metal cutting needs, thus maximizing both accuracy and productivity.

Understanding Tooth Geometry for Optimal Metal Cutting Performance

The effectiveness of a jigsaw in metal cutting greatly hinges on the tooth geometry of the blades used. Tooth geometry refers to the shape, pitch, and set of the teeth, which collectively influence cutting efficiency, speed, and surface finish. According to a report by the Metal Cutting Association, blades with high tooth counts and finer geometries are recommended for thin metals, such as aluminum and sheet steel, because they produce cleaner cuts and reduce burr formation. In contrast, for thicker materials, a lower tooth count with a more aggressive tooth angle can enhance the cutting speed and efficiency, allowing for quicker penetration into tough substrates.

Furthermore, the material of the jigsaw blade plays a critical role in tooth performance. Blades made from bi-metal or high-speed steel are preferred for their durability and heat resistance, which are essential when working with ferrous and non-ferrous metals. Industry studies indicate that the correct tooth geometry can improve cutting life by up to 30%, which translates into significant time and cost savings on projects involving repetitive cuts. Understanding the nuances of tooth design not only optimizes performance but also aids in selecting the right blade for specific applications, ensuring a balance between precision and productivity in metal cutting tasks.

Comparison of Bi-Metal vs. High-Speed Steel Jigsaw Blades

When it comes to cutting metal with a jigsaw, the choice of blade material is crucial for achieving precision and durability. The two primary types of jigsaw blades used for metal cutting are bi-metal and high-speed steel (HSS) blades. Bi-metal blades are comprised of a high-speed steel edge welded to a flexible steel body, providing a combination of toughness and wear resistance. According to industry reports, these blades are designed to handle metals such as aluminum, mild steel, and even stainless steel, making them a versatile choice for various applications. Their ability to maintain a sharp edge over prolonged use results in a cleaner cut and reduced heat generation during the cutting process, which is significant in preventing material warping.

On the other hand, high-speed steel blades offer a more cost-effective option for specific metal cutting tasks. These blades are made from high-speed steel, which retains hardness at elevated temperatures. However, while HSS blades can cut through softer metals efficiently, they may not perform as well when tackling harder materials compared to bi-metal options. Reports indicate that the lifespan of an HSS blade can be shorter when used on tougher metals, which can lead to increased costs in the long run, especially for professionals engaged in heavy-duty metal fabrication. Overall, understanding the differences between bi-metal and high-speed steel jigsaw blades is essential for selecting the right tool for the task at hand, ensuring both performance and cost-effectiveness in metalworking projects.

Best Brands for Metal Cutting Jigsaw Blades in 2023

When it comes to selecting the best jigsaw blades for metal cutting in 2023, it’s crucial to consider not only the blade materials but also the trusted brands behind these essential tools. According to a recent market analysis by Research and Markets, the demand for high-quality jigsaw blades has seen a significant rise, with the metal cutting segment projected to grow at a CAGR of 4.5% over the next decade. This growth is attributed to advancements in blade technology and the increasing use of jigsaws in both industrial and DIY applications.

Leading manufacturers have invested heavily in research and development to improve the performance and longevity of their jigsaw blades. Data from industry reports indicates that bi-metal blades, known for their superior durability and heat resistance, have become a top choice for professional metal workers. Furthermore, blades designed with fine teeth spacing allow for cleaner cuts, making them ideal for various metal types, including aluminum and stainless steel. As consumers become more discerning, the emphasis on brand reliability is more pronounced, with consumers likely to opt for brands that are synonymous with quality and innovation in metal cutting solutions.

Best 10 Jig Saw Blades for Metal Cutting in 2023

| Blade Type | Teeth per Inch (TPI) | Material | Cutting Thickness (mm) | Coating Type | Notes |

|---|---|---|---|---|---|

| Bi-Metal | 18 | High-Speed Steel | 3-10 | None | Ideal for heavy-duty cutting |

| Fine Tooth | 24 | High-Speed Steel | 1-4 | Titanium | Best for thin metals |

| Wood and Metal | 14 | Bi-metal | 2-6 | None | Versatile for mixed materials |

| Metal Cutting | 20 | Carbide | 3-8 | None | Designed for sheet metal |

| Extra Fine | 32 | High-Speed Steel | 1-3 | Black Oxide | For delicate cuts |

| Thick Metal | 10 | Bi-metal | 5-20 | None | Excellent for heavy gauge |

| All-Purpose | 16 | High-Speed Steel | 3-10 | Chrome Plated | Great for varied applications |

| Curved Metal | 18 | Bi-metal | 2-6 | Teflon Coated | Perfect for intricate shapes |

| Heavy Duty | 12 | Carbide | 6-12 | None | For toughest materials |

| Precision Cutting | 24 | High-Speed Steel | 1-4 | None | Best for fine details |

User Reviews and Ratings of Popular Jigsaw Blades for Metal

When it comes to cutting metal, choosing the right jigsaw blade is crucial for achieving precision and efficiency. User reviews and ratings provide valuable insights into the best options available in 2023. Many users emphasize the importance of blade material, with high-carbon steel and bi-metal options often receiving praise for their durability and performance. A common sentiment among reviewers is that blades designed specifically for metal cutting tend to offer smoother cuts, less friction, and longer lifespan, making them a preferred choice for DIY enthusiasts and professionals alike.

Additionally, ease of installation and compatibility with various jigsaw models are frequently mentioned in user feedback. Many reviews highlight the convenience of quick-change systems that allow for effortless blade swaps, saving time during projects. Regarding blade teeth design, users often note that finer tooth configurations provide cleaner finishes for intricate work, while more aggressive teeth help in faster cuts for thicker materials. Overall, user reviews serve as a helpful resource for anyone looking to invest in quality jigsaw blades, reflecting collective experiences that guide both novices and seasoned users in their selections.

Maintenance Tips for Prolonging the Life of Jigsaw Blades

To extend the lifespan of your jigsaw blades, proper maintenance is crucial. Regularly inspect the blades for any signs of wear or damage. Dull blades can lead to inefficient cutting and may bend or break during use. Replace any blades that show significant wear to maintain optimal cutting performance. Additionally, ensure that the blade is securely fastened before use to prevent it from loosening and causing potential accidents.

Another important maintenance tip is to clean the blades after each use. Dust, metal shavings, and residue can accumulate on the blade, affecting its performance. Using a soft cloth or a brush, gently remove debris to keep the blades in good condition.

If you frequently cut through different materials, consider dedicated blades for each task. This not only enhances their efficiency but also helps to keep them sharp for longer periods. Furthermore, storing blades in a protective case will shield them from moisture and accidental damage, maximizing their usability when you need them.

A Comprehensive Guide to Choosing and Using T118A Metal Cutting Jigsaw Blades for Precision Work

When it comes to precision metal cutting, selecting the right jigsaw blade is crucial for achieving the best results. The T118A metal cutting jigsaw blade is specifically designed for cutting materials less than 1/8-inch thick. This blade excels in handling sheet metal ranging from 10 to 16 gauge, making it an ideal choice for tasks involving thin metals that measure between 1/16-inch to 1/8-inch thick. Both ferrous and non-ferrous metals can be efficiently tackled with this blade, providing versatility for various projects.

Understanding the specific applications of the T118A blade is essential. According to industry reports, jigsaw blades designed for metal cutting must have the appropriate tooth geometry and high-quality material construction to optimize performance and longevity. For instance, blades with fine teeth provide cleaner cuts and reduce the likelihood of material deformation, which is critical in precision work. Additionally, quantitative studies indicate that the selection of the right blade can improve overall cutting efficiency by 30%, making the T118A a reliable choice for professionals and hobbyists alike.

In conclusion, the T118A metal cutting jigsaw blade stands out as an essential tool for precision work in metal fabrication. Its capability to cut through various types of thin metal with accuracy and ease allows users to achieve professional results without compromising on quality. As the demand for precision metal work continues to grow, using blades specifically designed for this purpose is increasingly recognized as a best practice within the industry.

FAQS

: Tooth geometry refers to the shape, pitch, and set of the teeth on a jigsaw blade, and it is important because it directly influences cutting efficiency, speed, and surface finish.

Blades with high tooth counts and finer geometries are recommended for thin metals, as they produce cleaner cuts and reduce burr formation, while lower tooth counts with aggressive angles are better for thicker materials, enhancing cutting speed and efficiency.

Blades made from bi-metal or high-speed steel are preferred for their durability and heat resistance, which are key when cutting ferrous and non-ferrous metals.

Understanding and selecting the correct tooth geometry can improve cutting life by up to 30%, resulting in significant time and cost savings for projects requiring repetitive cuts.

Users often praise high-carbon steel and bi-metal blades for their durability and performance, and note that blades specifically designed for metal cutting deliver smoother cuts and longer lifespans.

Many users find that ease of installation, particularly with quick-change systems, saves time during projects, making blade swaps more convenient.

Finer tooth configurations provide cleaner finishes and are better for intricate work, whereas more aggressive teeth assist in faster cuts for thicker materials.

A common sentiment is that blades designed for metal cutting offer improved performance, including less friction and smoother cuts, making them a favored choice among both DIY enthusiasts and professionals.

Conclusion

When selecting the best jig saw blades for metal cutting, it's essential to consider several key features. Look for materials specifically designed for metal cutting, such as bi-metal and high-speed steel (HSS) blades, known for their durability and performance. Understanding the tooth geometry is also crucial, as it affects the cutting efficiency and finish. Bi-metal blades offer flexibility and resistance to breaking, while HSS blades excel in speed and precision.

In 2023, the market showcases a variety of brands that produce high-quality jig saw blades metal, with user reviews providing insights into their performance. Careful maintenance can significantly extend the lifespan of these blades, enabling users to achieve optimal cutting results over time. By focusing on these features and reviews, metal cutting tasks can be performed with greater efficiency and effectiveness.

Related Posts

-

5 Surprising Benefits of Using Jig Saw Blades for Metal Cutting

-

10 Amazing Applications of the Best Wood Blade for Jigsaw: 5 Reasons Why It Raises Your Manufacturing Standards

-

Navigating Import and Export Certifications for Best Jig Saw Blades Metal Procurement

-

5 Essential Reasons to Choose the Best Blades For A Jigsaw

-

Top Strategies for Choosing the Best Fire Rescue Sawzall Blades for Maximum Efficiency

-

Unveiling the Future of Carbide Reciprocating Saw Blades at the 137th Canton Fair