7 Best Metal Reciprocating Blades for Precision Cutting

Table of Contents

- Top Features to Look for in Metal Reciprocating Blades

- How Metal Reciprocating Blades Enhance Precision in Cutting

- Comparing Different Types of Metal Reciprocating Blades

- Applications Where Precision Cutting with Metal Blades is Essential

- Tips for Choosing the Right Metal Reciprocating Blade for Your Projects

- FAQS

- Conclusion

- Related Posts

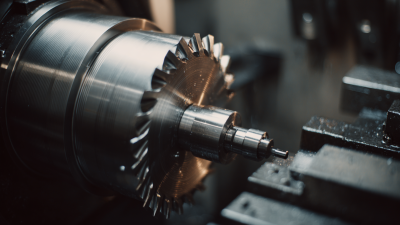

When you're into precision cutting, picking the right tools really makes a big difference in both the quality and how smoothly your work goes. Metal reciprocating blades, in particular, are definitely worth considering—they're sturdy, versatile, and pretty much indispensable whether you're a pro or just someone messing around with DIY projects. At Wenzhou Yichuan Tools Co., Ltd., we've been around since 2003, focusing on making top-notch jigsaw blades, reciprocating saw blades, and planers to cover pretty much any cutting need. We totally get how crucial it is to choose the right metal reciprocating blades for different jobs — it means cleaner cuts and better performance all around. So, in this post, I want to walk you through the seven best metal reciprocating blades out there. They not only come with some awesome benefits but can really boost your cutting game and make your projects easier and more enjoyable.

Top Features to Look for in Metal Reciprocating Blades

When you're choosing metal reciprocating blades, it’s really important to keep a few key features in mind—these little details can totally affect how precise and how well the blades perform. For starters, pay attention to what the blades are made of. High-carbon steel and bi-metal blades are pretty popular because they’re tough and resist wear pretty well. I came across a report from Freedonia Group that says demand for metal cutting tools is expected to go up nearly 4.5% each year until 2026. That’s partly because of new tech in blades that boost cutting efficiency—pretty cool, right?

Another thing to consider is the tooth design, especially how many teeth per inch (or TPI) the blade has. Blades with more teeth per inch are usually better if you’re doing smooth cuts on thin materials. On the flip side, blades with fewer teeth tend to go faster — great for chopping through thicker metals. IBISWorld even mentioned that companies focusing on precision cutting tools are looking at a pretty solid boost in the market share. Oh, and don’t forget about the thickness and length of the blade—these can really impact stability, especially when you’re tackling tricky jobs. Picking the right blade for your specific project can make a big difference in how accurate your cuts are and how long your tools last in the long run.

How Metal Reciprocating Blades Enhance Precision in Cutting

Metal reciprocating blades are pretty much 必不可少 in construction and fabrication work, especially when you need really precise cuts. I recently read from the Manufacturing Institute that using top-notch blades can boost your cutting accuracy by up to 30%. That’s a big deal because it means cleaner cuts and way less material wasted. And let’s be honest, when you're dealing with metals like steel or aluminum, even a tiny slip-up can cause all sorts of problems during assembly and rack up the labor costs.

On top of that, tech has come a long way when it comes to these blades. There’s now really cool bi-metal versions that, according to the Precision Machined Products Association, last about twice as long as regular blades. That’s huge because they stay sharp longer, which helps keep precision spot-on and cuts down the need to replace blades constantly. Plus, for folks doing a lot of metal cutting, these advanced blades can save a ton of money in the long run. Bottom line? If you’re into high-volume or super accurate work, upgrading to these newer, better blades can make all the difference—less mistakes, more efficiency, and better results overall.

Comparing Different Types of Metal Reciprocating Blades

When you're dealing with precision metal cutting, choosing the right reciprocating blades is actually pretty crucial. There are all sorts of different types out there, each offering their own perks and performance traits. For example, high-speed steel (or HSS) blades are pretty much known for their toughness and ability to handle heat, making them a solid pick when you're cutting tough metals. On the other hand, bi-metal blades, which have HSS teeth attached to a flexible steel body, are super resilient and versatile—great for a whole bunch of different jobs.

Now, on the cutting-edge—no pun intended—research at Zhejiang University has made some pretty exciting progress in the field of metal nano-materials. Thanks to national science foundation funding, scientists there are diving deep into how grain boundaries migrate in metals, which could totally change how we process materials in the future. This kind of research just goes to show how important the material properties are—something that also matters when you're picking out reciprocating blades. Basically, you want to choose blades that are right for the specific metal you're working with and that match your cutting conditions like speed and thickness.

Pro tip: When you're picking a metal reciprocating blade, keep in mind the material and how thick it is. For cleaner, smoother cuts, go for blades with finer teeth. And don’t forget—using the right blade speed can really make a difference, helping the blade last longer and giving you more precise, efficient cuts. So, yeah, a little bit of planning can go a long way toward getting those perfect cuts every time.

Applications Where Precision Cutting with Metal Blades is Essential

When you're talking about spot-on precision in cutting, metal reciprocating blades are honestly a game-changer. These blades are made to tackle tough stuff—think steel, aluminum, and other heavy metals—so they're pretty much essential whenever you need accuracy and dependability. Industries like construction, manufacturing, and auto work? They rely on these blades for those tricky, detail-oriented cuts. Whether you're tearing down old buildings or crafting metal parts, having the right blade can make a huge difference—speeding things up and making sure everything’s just right, so the final result hits those high standards.

Plus, one of the best things about metal reciprocating blades is how versatile they are. They’re great for everything from fine-tuning metal frames to squeezing into tight spots to make precise cuts. Whether you’re installing pipes or making custom fittings, high-quality blades with sharp edges and durability are what pros reach for. And with all the recent tech improvements, you can now cut cleaner and minimize the risk of messing up the material—making your workflow smoother and less stressful. Picking the right metal blades for your project? It totally ups your game and ends up making you more satisfied with the results, no doubt about it.

Tips for Choosing the Right Metal Reciprocating Blade for Your Projects

When you're working on metal, picking the right reciprocating blade is kinda key if you want those clean, precise cuts. First off, you gotta think about what kind of metal you're slicing through—stuff like aluminum, steel, or stainless steel all have different needs. For softer metals like aluminum, a blade with fewer teeth per inch (TPI) is usually the way to go since it cuts quicker. But if you're dealing with denser metals, you'll probably want something with a higher TPI—it helps make smoother cuts and cuts down on vibration.

Also, the blade material makes a big difference. For example, bi-metal blades are pretty versatile—they're flexible yet durable, so they work for a bunch of projects. On the other hand, carbide-tipped blades pack more punch, especially on tougher metals, but yeah, they tend to cost more. Don't forget about blade length either—longer blades can get into tighter spots, but shorter ones are generally more maneuverable if you're doing detailed work. Basically, understanding these little details will help you pick the right blade and make your cutting jobs way easier and more accurate.

7 Best Metal Reciprocating Blades for Precision Cutting - Tips for Choosing the Right Metal Reciprocating Blade for Your Projects

| Blade Type | Material | Teeth Per Inch (TPI) | Length | Cutting Capacity | Best For |

|---|---|---|---|---|---|

| Bi-metal Blade | High-speed Steel | 14 | 9 inches | Up to 3/8 inch metal | General metal cutting |

| Carbide Tipped Blade | Carbide | 10 | 12 inches | Up to 1 inch metal | Thick metal cutting |

| High Carbon Steel Blade | High Carbon Steel | 8 | 6 inches | Up to 1/4 inch metal | Light metal projects |

| Titanium Coated Blade | Steel with Titanium | 12 | 9 inches | Up to 5/16 inch metal | Versatile cutting |

| Wood and Metal Blade | HCS and HSS | 6 | 12 inches | Up to 1/2 inch metal | Mixed material cutting |

| All-Purpose Blade | High-speed Steel | 10 | 9 inches | Up to 3/8 inch metal | General use |

| Specialty Blade | HSS | 14 | 6 inches | Specialized cuts | Unusual materials |

FAQS

: Metal reciprocating blades are essential tools in the construction and fabrication industries, primarily used for precision cutting of various metals.

High-quality reciprocating blades can improve cutting accuracy by up to 30%, which leads to cleaner cuts and reduced material wastage.

Precision is crucial in metal cutting because even minor deviations can complicate assembly processes and increase labor costs.

Bi-metal technology enhances the lifespan of metal reciprocating blades, making them last 50% longer than standard blades while maintaining cutting precision.

Key factors include the type of metal being cut, the blade material, and the blade length, as different metals and cuts require different blade configurations.

Bi-metal blades offer a balance of flexibility and durability, making them suitable for various cutting tasks while prolonging the blade's lifespan.

Carbide-tipped blades provide superior cutting power for tougher materials, but they are generally more expensive than bi-metal blades.

Softer metals like aluminum benefit from blades with fewer teeth per inch (TPI) for faster cuts, while denser metals require a higher TPI for smoother cuts.

Longer blades can reach into tighter spaces, while shorter blades are often more maneuverable, making them better for intricate cuts.

Enhanced metal reciprocating blades minimize errors and maximize efficiency in cutting tasks, leading to superior results in metalwork.

Conclusion

When you're tackling precision cutting jobs, picking the right Metal Reciprocating Blades is pretty much essential if you want that perfect finish. In our latest blog, we break down the key features you should keep in mind—stuff like the blade material, tooth design, and whether it jives with your tools. We also compare different types of these blades, showing how specific designs can really boost accuracy. That’s especially handy if you’re into metal fabrication or fixing up cars, where attention to detail really counts.

Here at Wenzhou Yichuan Tools Co., Ltd., we've been around since 2003, mainly focusing on making high-quality electric tool accessories—think jigsaw blades, reciprocating saw blades, and the like. Whether you're a pro or just someone into DIY projects, we’re here to help you pick the right blade for your needs. Our goal is to make sure your cuts are precise and efficient, so you get the job done right the first time.

Hope this gives you a clearer idea—happy cutting!

Related Posts

-

7 Incredible Facts About the Best Metal Reciprocating Blades You Need to Know

-

Issues with Selecting the Right Reciprocating Saw Blades for Tree Pruning

-

Navigating Import Export Certifications for Best Sabre Saw Blades in Global Markets

-

Unleashing the Power of Chinese Manufacturing with Top Tier Cast Iron Cutting Blades

-

How to Minimize Maintenance Costs with Superior After-Sales Support for Best Metal Reciprocating Blades

-

China Manufacturing Thrives Amid US China Tariff Challenges with Best Sawzall Blade Insights