How to Choose Recip Saw Blades for Metal Cutting?

Table of Contents

- Understanding Recip Saw Blades and Their Uses in Metal Cutting

- Types of Recip Saw Blades Suitable for Metal Cutting

- Key Factors to Consider When Choosing Recip Saw Blades

- Blade Material Options for Optimal Metal Cutting Performance

- Tooth Design: Impact on Cutting Speed and Quality

- Compatibility with Different Reciprocating Saws

- Maintenance Tips for Prolonging Blade Life in Metal Cutting

- FAQS

- Conclusion

- Related Posts

Picking the right recip saw blades for cutting metal isn’t always straightforward, and honestly, it can get kinda overwhelming with all the options out there. Every blade has its own purpose, so knowing what you really need can actually save you a lot of time and headache. Think about the type of metal you're working with — thicker metals, for example, usually need blades with more aggressive teeth to do the job efficiently. It’s all about choosing the right tool for the task. Also, pay attention to how the blade is built; whether it’s high-speed steel or bi-metal makes a pretty big difference in performance. There are tons of brands like DEWALT or Bosch that make decent options, but sometimes you gotta ask yourself: will this one actually work for my project? Honestly, trying out different blades can sometimes lead to surprising results — in a good way! So, don’t be afraid to experiment a little — it might just save you some hassle and improve your work overall.

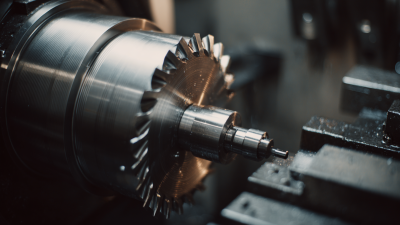

Understanding Recip Saw Blades and Their Uses in Metal Cutting

Recip saw blades play a crucial role in metal cutting. Their design and material significantly impact performance. A standard blade has multiple teeth, which helps maintain a smooth cut. The tooth count can vary based on the specific metal being cut. For instance, a blade with fewer teeth is better for thicker materials, while more teeth excel in thinner metals.

Understanding blade material is also essential. High-carbon steel blades are common but can wear out quickly. Bi-metal blades combine toughness and flexibility, making them popular. They resist wear and handle heat well. An often-overlooked aspect is the blade's thickness, which can affect cutting speed. Thicker blades tend to be sturdier, but they may demand more power from the tool.

Choosing the right blade can be challenging. Many users may underestimate the importance of tooth design. Some users might experience frustration when cuts go off track. Learning from mistakes is key. Always make sure to match the blade specifications with the material type. It's a small yet significant detail that can affect the entire project.

Types of Recip Saw Blades Suitable for Metal Cutting

When it comes to cutting metal with a reciprocating saw, choosing the right blade is crucial. Several types of blades are designed specifically for metal cutting. Bi-metal blades combine flexibility and durability. They can withstand high stress and are ideal for heavy-duty tasks. Carbide-grit blades feature a coating that excels in cutting through hard materials. These blades last longer in abrasive conditions.

Tips: Consider the material thickness. For thinner metals, a blade with a higher tooth count works best. Thicker metals often require fewer teeth per inch for effective cutting.

For light metal applications, high-speed steel blades are sufficient. They are budget-friendly but wear out faster. On the other hand, for tougher jobs, stainless steel or aluminum might demand more specialized blades. Industry reports indicate that using the correct blade can improve cutting efficiency by up to 30%. This can save time and reduce frustration.

It is essential to assess your project needs. A mismatched blade can lead to poor performance and wasted resources. Invest in the right type, and you will see significant improvements in your cutting tasks.

Key Factors to Consider When Choosing Recip Saw Blades

When choosing reciprocating saw blades for metal cutting, several important factors come into play. The type of metal you are cutting matters. Stainless steel, for instance, requires different blades compared to aluminum. Ensure the blade's tooth design suits the specific metal. For thicker materials, a larger tooth pitch is necessary. A finer tooth pitch works better for thinner metals.

Another factor to keep in mind is the material of the blade itself. Bi-metal blades are popular for their durability. They combine flexibility and strength, making them suitable for various metals. However, they may not excel in extreme conditions. Think about what you are cutting. A blade that is too hard can become brittle. This can lead to unexpected breaks and inefficiency.

Also, take note of the blade length. Longer blades are beneficial for deep cuts but may be cumbersome for tighter spaces. A shorter blade can offer better control but limits cut depth. It’s essential to reflect on your project needs and cut the right balance. Each choice influences your cutting efficiency, precision, and overall success. Sometimes, it requires trial and error to find what truly works for your specific cutting tasks.

Blade Material Options for Optimal Metal Cutting Performance

When selecting recip saw blades for metal cutting, the material of the blades plays a crucial role in performance. Common blade materials include high-speed steel (HSS), bi-metal, and carbide-tipped designs. High-speed steel offers decent durability for light-duty tasks. However, it may not withstand high temperatures and wear over time. Reports indicate HSS is less effective for thick or tough metals.

Bi-metal blades combine flexibility and strength, making them a preferred choice for many professionals. They can cut through various metal types. Research shows that bi-metal blades maintain their sharpness longer than standard HSS blades. This translates to increased efficiency and less time spent on blade changes.

Carbide-tipped blades are another excellent option for heavy cutting tasks. They can handle harder materials and maintain their performance under extreme conditions. Yet, they come at a higher cost. Industry studies suggest that while the investment is significant, the longevity and performance of carbide-tipped blades may justify the expense.

However, users must evaluate if such an investment aligns with their cutting needs. Is it worth the initial cost? Only time will tell as users experience the performance firsthand.

Tooth Design: Impact on Cutting Speed and Quality

Tooth design plays a pivotal role in the performance of recip saw blades for metal cutting. The shape and size of the teeth can significantly influence cutting speed and overall quality. For instance, blades with aggressive tooth geometry tend to facilitate quicker cuts. A study showed that blades with a pitch of 3 to 4 teeth per inch increase cutting speed by approximately 15% compared to those with finer teeth.

Using fewer teeth can create faster cuts, but it often compromises the quality of the finish. Blades with higher tooth counts produce smoother cuts but slow down the process. According to a report by a leading manufacturing resource, the ideal tooth design balances speed and quality. The report suggests that a pitch that allows an optimal number of teeth in contact with the material is critical.

However, achieving this balance is not always straightforward. Users must consider the type of metal being cut and adjust their choice accordingly.

Moreover, the material of the blade itself interacts with tooth design. Blades made of high-speed steel (HSS) or carbide-tipped varieties often perform better under heavy loads. However, they can be less forgiving of user errors. An HSS blade may dull quickly if used improperly, while carbide-tipped blades resist wear but tend to be more brittle. Adjusting to the right setup takes practice. Understanding these nuances can enhance cutting efficiency, yet it often requires experience to perfect.

Compatibility with Different Reciprocating Saws

Choosing the right reciprocating saw blade for metal cutting is crucial. Compatibility with different reciprocating saws can directly affect your work. Each saw has specific requirements for blade types and sizes. Not all blades fit all saws seamlessly. A mismatch may lead to poor performance or even damage.

Consider the mounting system of your saw. Some use a keyhole system, while others employ a universal chuck. Knowing your saw's requirements can help narrow down suitable blades. Blade length matters too. Standard lengths range from 6 to 12 inches. A longer blade might not fit in smaller saws well. Always check specifications.

Look at blade material. High-speed steel and bi-metal options are popular for metal. They provide durability and longevity. However, some users find that softer blades wear out quickly. It’s a trade-off. Test various blades to find your ideal balance. Learning from trial and error will refine your choices over time.

Maintenance Tips for Prolonging Blade Life in Metal Cutting

When it comes to maintaining recip saw blades for metal cutting, proper care is crucial. A well-maintained blade lasts longer and performs better. This is not just about cleaning. It’s also about how you handle and store your blades.

Tips: Always store your blades in a dry place. Humidity can lead to rust. Regularly clean your blades to remove any metal shavings or debris that could dull the edge. A quick wipe with a cloth can make a difference.

Inspect your blades frequently. Look for signs of wear or damage. If you notice chips or cracks, it’s best to replace the blade. Cutting through harder metals can cause more wear than expected. Sometimes, it's easy to overlook small damages that can affect cutting efficiency.

Don’t rush the cutting process. Patience allows the blade to do its job effectively. Forced cutting generates heat, which can wear down the blade quickly. Keep the work area organized to avoid unnecessary accidents and damage to your tools.

FAQS

: The article aims to provide useful information on various topics.

It is intended for individuals seeking knowledge on specific subjects.

The content is structured in a clear and concise manner for easy understanding.

The information comes from reliable sources, but always verify independently.

Yes, the article suggests looking into related materials for deeper understanding.

Yes, it includes insights from professionals in the field.

The article encourages readers to explore the topics further and ask questions.

Visual aids may accompany the text to enhance understanding.

It admits that some details might be oversimplified or outdated.

You can leave comments or share your thoughts for discussion.

Conclusion

When selecting Recip Saw Blades for metal cutting, it is essential to understand their specific uses and the various types available. Factors to consider include the blade material, which affects performance, and the tooth design, which plays a crucial role in determining cutting speed and quality. Choosing the right blade also involves ensuring compatibility with different reciprocating saws, as not all blades fit all models.

To maximize the service life and efficiency of Recip Saw Blades Metal, regular maintenance is key. Proper care will not only enhance cutting performance but also prolong the lifespan of the blades. By understanding these critical aspects, users can make informed decisions to achieve optimal results in their metal cutting tasks.

Related Posts

-

Top 10 Recip Saw Blades for Metal Cutting: Expert Reviews & Performance Data

-

Unlock Precision Cutting: The Ultimate Guide to 12 Reciprocating Saw Blades for Global Buyers

-

Discover Quality and Innovation with Reciprocating Saw Blade Set at the 137th Canton Fair 2025

-

Exploring the Future of Best Sawzall Blades Metal Trends for 2025 Global Buyers

-

5 Essential Tips for Choosing the Best Recip Saw Blades for Metal

-

How to Minimize Maintenance Costs with Superior After-Sales Support for Best Metal Reciprocating Blades