The Ultimate Guide to Choosing the Right 18 Inch Reciprocating Saw Blade for Your Projects

Table of Contents

- Understanding the Different Types of 18 Inch Reciprocating Saw Blades

- Key Factors to Consider When Selecting a Reciprocating Saw Blade

- Material Matters: Choosing the Right Blade Composition

- Teeth Per Inch (TPI): What You Need to Know for Your Cutting Tasks

- Top Brands and Recommendations for Quality 18 Inch Blades

- Maintaining Your Reciprocating Saw Blades for Longevity and Performance

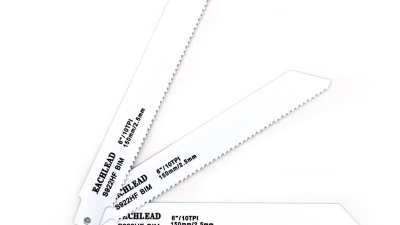

- Maximize Your Cutting Efficiency: The S922VF 6 Inch Reciprocating Saw Blade Review and Tips

- FAQS

- Conclusion

- Related Posts

When you’re dealing with power tools, picking the right accessories can really make a difference—both in how good your project turns out and how smoothly everything goes. Take the 18 Inch Reciprocating Saw Blade, for example; it’s basically a must-have for both pros and DIY folks alike. It lets you make precise cuts in all sorts of materials, from wood to metal, without too much hassle. You know, industry reports show that demand for these blades has been steadily climbing, and it’s expected to grow by nearly 5% each year—that just goes to show how重要it is to choose the right blade for whatever task you’ve got at hand. Here at Wenzhou Yichuan Tools Co., Ltd., we kicked things off back in 2003, focusing on making top-quality electric tool accessories—reciprocating saw blades included—to meet all sorts of needs. We’re all about quality, so whether you’re just doing a quick job around the house or tackling a big construction project, you can count on having the right tools to get it done right.

Understanding the Different Types of 18 Inch Reciprocating Saw Blades

So, when you're trying to pick out the perfect 18-inch reciprocating saw blade, it really helps to understand the different types out there. Honestly, there are usually three main kinds: wood blades, metal blades, and the bi-metal ones—each designed for specific materials and cutting jobs. Funny enough, according to a report from IBISWorld, the demand for power tools, especially reciprocating saws, is expected to grow about 5.4% every year over the next five years. That just shows how much these versatile tools are becoming a staple in both professional and DIY projects.

Now, wood blades usually come with coarser teeth, which makes them great for making quick cuts in softwood or hardwood. If you look at a blade with around 6 to 8 teeth per inch (TPI), that's usually your best bet. On the flip side, metal blades tend to have finer teeth—somewhere between 14 and 18 TPI—to make precise cuts through different metals. Then there are bi-metal blades, which are kind of the best of both worlds—they combine high-speed steel and carbon steel, so they’re durable enough for tough cuts and versatile enough for mixed-material projects. Interestingly, a study from the Power Tool Institute mentions that choosing the right blade can boost your cutting efficiency by up to 30%. That means you can get the job done faster and with less wear and tear on your blades—pretty cool, right?

Key Factors to Consider When Selecting a Reciprocating Saw Blade

When you're looking to pick out the right 18-inch reciprocating saw blade, there are a few key things to keep in mind to make sure you get the best performance for your project. First off, think about what material you’re planning to cut. Different blades are made for different stuff—whether it’s wood, metal, or composites—you really want to match the blade to your task. For example, blades designed for wood usually have aggressive teeth that cut quickly, while ones meant for metal tend to have finer teeth to prevent chipping and give you cleaner, more precise cuts.

When you're looking to pick out the right 18-inch reciprocating saw blade, there are a few key things to keep in mind to make sure you get the best performance for your project. First off, think about what material you’re planning to cut. Different blades are made for different stuff—whether it’s wood, metal, or composites—you really want to match the blade to your task. For example, blades designed for wood usually have aggressive teeth that cut quickly, while ones meant for metal tend to have finer teeth to prevent chipping and give you cleaner, more precise cuts.

Another thing to consider is the tooth count and how the teeth are arranged. Blades with fewer teeth tend to be great for making quick cuts, especially in softer materials. On the flip side, blades with more teeth are usually better if you’re working with harder stuff or need detailed, cleaner cuts. Interestingly, data shows that the reciprocating saw market is expected to hit around $64 billion by 2023, growing at about 4.12% annually from 2024 to 2031. That’s a clear sign that people are really into quality tools these days, and choosing the right blade can seriously make or break your results. So, take your time and think through these factors—they’ll help you pick the best blade for what you’re working on and get professional-looking results without the hassle.

Material Matters: Choosing the Right Blade Composition

When you're picking out an 18-inch reciprocating saw blade, one of the most important things to consider is what the blade’s made of. Honestly, the material really affects how well it works and how long it lasts. Most blades are either made from high-speed steel (HSS), bi-metal, or carbide-tipped parts. From what I’ve read, bi-metal blades—which basically have HSS teeth attached to a flexible steel body—are pretty popular because they last longer and are less likely to break. Plus, they’re pretty versatile, great for tackling all sorts of materials, whether you’re tearing down something or doing some construction work.

Lately, I’ve also come across some stats showing that carbide-tipped blades can go much further—like, they last a lot longer—especially when you're cutting tough stuff like concrete or metal. Actually, some reports say you can get up to 50% more life out of these compared to regular steel blades. Sure, they cost a bit more upfront, but they might save you money in the long run. On the flip side, HSS blades are decent for softer materials, but they tend to wear out faster, so they’re not the best choice for heavy-duty jobs. Basically, knowing the pros and cons of each type can help you pick the right blade, so your work’s more efficient and you don’t end up wasting time or money on the wrong tool for the job.

Teeth Per Inch (TPI): What You Need to Know for Your Cutting Tasks

When you're choosing an 18-inch reciprocating saw blade, it's pretty important to get a handle on Teeth Per Inch (TPI). Basically, TPI tells you how many teeth are packed into each inch of the blade, and that really affects how smoothly and efficiently it cuts.

Usually, if you're after fine, detailed work, going for a higher TPI—say, above 14—is the way to go. Those extra teeth make for a cleaner cut and less risk of tearing out the material. On the other hand, if you're dealing with thicker stuff like metal or thinner materials, blades with a lower TPI—around 3 to 10—are your friends. They cut faster and more aggressively, which is perfect when speed matters more than perfect finish.

Understanding what the TPI on your blade means can really help you pick the right tool for the job. It makes all the difference between a smooth, precise cut and a rough one. The key is to match the TPI to what you're working on—this way, you'll get better results and make your project a lot easier to handle.

Top Brands and Recommendations for Quality 18 Inch Blades

When you're trying to pick out the right 18-inch reciprocating saw blade for your project, it's pretty important to think about more than just the material you'll be cutting. You should also pay attention to the little features that set the top brands apart. Industry pros often say that choosing the right blade can make a big difference—helping you cut more efficiently and tackling tough jobs easier. For example, blades with high-quality bi-metal or carbide tips are known to last longer, reducing the need for frequent replacements and helping you stay productive.

Some brands tend to stand out among professionals. Recent tests have shown that things like tooth design and blade shape really matter—they can influence how precise and quick your cuts are. If you want to cut faster, blades with more aggressive teeth are your friends. But if you’re after a cleaner, smoother finish, then blades with finer teeth are better. Just keep in mind, choosing the right blade isn’t just about performance; it also affects safety and control, which is super important whether you're doing projects at home or working professionally.

Maintaining Your Reciprocating Saw Blades for Longevity and Performance

Taking good care of your reciprocating saw blades is absolutely key if you want them to last longer and work their best, especially when you're juggling different projects. A blade that's well-maintained doesn’t just cut better—it actually helps keep your whole tool in good shape. Make it a habit to check your blades regularly for any signs of wear or damage; this can save you from overheating and ensures you get clean, smooth cuts every single time.

Here's a quick tip: after you're done using your blades, give them a good cleaning. Just remove any gunk or resin buildup—nothing fancy, a bit of soapy water and a soft brush usually does the trick. Oh, and don’t forget to rotate your blades now and then; it helps them wear evenly and can really extend their lifespan.

When picking out a blade, think about what material you’re cutting—be it wood, metal, or some composite material. Using the right blade for the job can make a huge difference in both the quality of your work and how smoothly everything goes. Whether you’re a pro or just doing some DIY, investing in high-quality blades is totally worth it. It’ll help you get the results you want while keeping your tools in top shape.

Maximize Your Cutting Efficiency: The S922VF 6 Inch Reciprocating Saw Blade Review and Tips

When it comes to maximizing your cutting efficiency, the S922VF 6 Inch Reciprocating Saw Blade stands out as a versatile tool for both professionals and DIY enthusiasts. This blade is suitable for a wide array of materials, including metal and wood, making it an essential companion in various industries such as automobile manufacturing, shipbuilding, and furniture production. According to a recent industry report by IBISWorld, the demand for reciprocating saws in the construction and manufacturing sectors has seen an annual increase of 4.1% over the past five years, highlighting the importance of effective cutting tools.

One of the standout features of the S922VF blade is its ability to conveniently cut through thick tree roots, which is especially useful for landscaping and maintenance projects. This capability allows users to navigate tight spaces, such as cutting roots under fences without disturbing the surrounding area. Additionally, its design enables straight cuts through wood containing nails, ensuring high precision and a clean finish. The blade's performance is backed by user testimonials that emphasize its effectiveness and durability in heavy-duty applications.

Furthermore, extensive research indicates that tools like the S922VF can significantly enhance productivity on job sites. A report from the National Association of Home Builders suggests that the right cutting tools can reduce project time by as much as 20%, providing not only time savings but also improving overall work quality. As industries evolve and efficiency becomes more critical, investing in high-quality tools like the S922VF reciprocating saw blade is a smart choice for maintaining a competitive edge in the market.

FAQS

: The main types are wood blades, metal blades, and bi-metal blades, each designed for specific materials and cutting applications.

Wood blades, which have coarse teeth and typically a tooth count of 6 to 8 teeth per inch (TPI), are best for quick cuts in softwood and hardwood materials.

Metal blades have finer teeth, usually ranging from 14 to 18 TPI, which ensures precision when cutting through various metals, unlike wood blades which are designed for speed in softer materials.

Bi-metal blades combine high-speed steel and carbon steel, offering durability for metal cutting and versatility for mixed-material projects.

Using the appropriate blade type can enhance cutting efficiency by up to 30%, allowing for more effective task completion while reducing wear on the blade.

Common materials include high-speed steel (HSS), bi-metal, and carbide-tipped materials, each affecting performance and longevity differently.

Bi-metal blades are favored for their durability and resistance to breakage, making them suitable for a wide range of materials in both demolition and construction applications.

Carbide-tipped blades can last significantly longer than traditional steel blades, particularly when cutting tough materials, with users potentially seeing up to a 50% increase in blade life.

HSS blades offer good performance for softer materials but may wear out quicker and are not ideal for heavy-duty tasks compared to bi-metal or carbide-tipped options.

It is essential to understand the strengths and weaknesses of each blade type and material composition to optimize efficiency and meet specific project needs.

Conclusion

When you're trying to pick out the right 18-inch reciprocating saw blade for your projects, there are actually quite a few things you should keep in mind. Knowing the differences between the various types of blades is pretty important—they’re each designed for specific tasks, whether you're cutting wood, metal, or other materials. The blade’s material and build also matter a lot because they affect how long the blade lasts and how smoothly it cuts. Oh, and don’t forget about the teeth per inch (TPI); that tiny detail influences how clean and fast your cut will be. So, choosing the right TPI based on what you're working on is kinda essential.

At Wenzhou Yichuan Tools Co., Ltd., we’re all about making high-quality reciprocating saw blades for both pros and DIYers alike. Since 2003, we’ve been focused on electric tool accessories, so you can count on us to offer reliable, durable blades—especially our 18-inch options from some of the best brands out there. Whatever your cutting project is, you can feel good knowing we’ve got tools that will get the job done. And a quick tip—regularly maintaining your blades can really make a difference in how long they last and how well they perform. Ultimately, a good blade isn’t just a tool; it’s an asset to your workshop.

Related Posts

-

Unlock Precision Cutting: The Ultimate Guide to 12 Reciprocating Saw Blades for Global Buyers

-

Top 10 24-Inch Sawzall Blades from Chinese Manufacturers at the 137th Canton Fair

-

Issues with Selecting the Right Reciprocating Saw Blades for Tree Pruning

-

How to Choose the Best Short Reciprocating Saw Blades for Your Next Project

-

Unlocking Efficiency with the Best Reciprocating Saw Blades Screwfix for Global Procurement Success

-

Navigating Import Export Certifications for Best Sabre Saw Blades in Global Markets