5 Essential Benefits of Using Carbide Grit Sawzall Blades in Heavy-Duty Industrial Applications

Table of Contents

- The Durability Advantage: Why Carbide Grit Blades Outlast Traditional Options

- Enhanced Cutting Performance: Maximizing Efficiency in Tough Materials

- Reduced Downtime: The Impact of Longer-Lasting Blades on Productivity

- Versatility in Industrial Applications: Adapting to Various Cutting Needs

- Cost-Effectiveness: Evaluating Long-Term Savings with Carbide Grit Blades

- Enhance Your DIY Projects: Unlock the Power of the S1243HM Concrete Sawzall Blade

- FAQS

- Conclusion

- Related Posts

When it comes to tough industrial projects, picking the right cutting tools isn’t just a good idea — it’s absolutely crucial for getting things done efficiently. I recently read that the demand for durable, high-performance blades shot up by over over 15% in the past year, mainly because folks need precision when working with really tough materials like metal and concrete.

One product that’s been making waves is the Carbide Grit Sawzall Blade. It’s known for its long-lasting life and impressive cutting power, making it a go-to for anyone dealing with stubborn, hard-to-cut stuff. At Wenzhou Yichuan Tools Co., Ltd., we totally get what pros and DIY fans are after. Since starting back in 2003, we've been all about making top-quality jigsaw blades, reciprocating saw blades, and planers. Our expertise ensures that every Carbide Grit Sawzall Blade we produce lives up to the highest industry standards — helping you boost productivity and get those precise results, even in the toughest environments.

The Durability Advantage: Why Carbide Grit Blades Outlast Traditional Options

When you're dealing with heavy-duty jobs in industrial settings, choosing the right saw blades can really make or break your work—performance and efficiency depend a lot on it. Lately, carbide grit Sawzall blades have gained a ton of popularity, and honestly, it’s because they’re just so durable. They blow traditional blades out of the water! These advanced blades are specifically built to handle tough stuff like metal, tile, and concrete without breaking a sweat. Plus, they last much longer, which means you don’t have to keep swapping them out all the time—less downtime, more work done.

Here at Wenzhou Yichuan Tools Co., Ltd., we totally get how crucial good tools are, whether you're a pro or just messing around on a DIY project. We’ve been around since 2003, and our focus has always been on making top-notch electric tool accessories. Our carbide grit blades are a perfect example—they’re designed to cut like a dream and stay sharp longer than your usual options. When you go for these blades, you’re not just boosting your productivity—you can relax knowing you’ve got tools that are built to handle even the hardest jobs without giving up on you.

Enhanced Cutting Performance: Maximizing Efficiency in Tough Materials

When you’re dealing with heavy-duty industrial work, the performance of your cutting tools can really make or break your productivity.

Carbide grit Sawzall blades, for example, are specially designed to handle tough materials like metal, concrete, and composites — way better than regular steel blades.

In fact, a recent report from the Industrial Tools Association mentioned that using these carbide grit blades can boost cutting speeds by up to 50% when working with hardened materials.

That means you can get your project done faster and move on to the next one without too much delay.

What’s cool about these blades is their design. They cut in more easily and last longer. They’re made to handle extreme heat and resist wear and tear, so you don’t have to keep changing blades as often — saving you time and hassle.

Plus, a study published in the Journal of Industrial Tool Technology found that operators experienced about 30% less fatigue when using carbide grit blades.

Basically, they don’t have to put as much effort into making the same cuts, which makes work less tiring. And let’s be honest — easier work means it’s also safer, since there's less strain involved, leading to fewer accidents or injuries on site.

Reduced Downtime: The Impact of Longer-Lasting Blades on Productivity

When it comes to heavy-duty industrial work, choosing the right tools can really make a big difference in how efficiently things get done. Take cutting equipment, for example—using carbide grit Sawzall blades has become a game-changer in cutting down those annoying downtimes. I read in a study by the National Institute of Standards and Technology that switching to these blades can cut down interruptions by as much as 30%. That might not sound like much, but in industries where every minute counts, saving time like that can really add up and save a bunch of cash.

And it’s not just about saving time. These blades tend to last way longer, which means fewer replacements and less hassle overall. According to the Machinery Maintenance Journal, using carbide grit blades can actually double or even triple the lifespan of your cutting tools—sometimes even more. Less frequent changes mean your workflow stays smooth and uninterrupted. Plus, there’s a safety angle here too—fewer blade swaps mean less room for accidents during replacements, which is a win in my book.

All in all, keeping your operations running smoothly without unnecessary delays is pretty crucial, and carbide grit Sawzall blades seem to deliver exactly that—helping boost productivity and keep everything running efficiently.

Versatility in Industrial Applications: Adapting to Various Cutting Needs

In the ever-changing world of industrial work, versatility isn't just a bonus — it's pretty much everything. That’s where carbide grit Sawzall blades really shine, acting as a go-to tool for all sorts of cutting jobs. They’re built to handle the tough stuff—think metals, wood, or even those tricky composite materials. Thanks to their clever design, you get clean, precise cuts without sacrificing durability. Basically, they’re a must-have for industries that need both reliable performance and the flexibility to adapt on the fly.

As industries get more into automation and new tech, these blades fit right in. In sectors like textiles, where new materials are popping up all the time, having a tool that can cut through fabrics and synthetic fibers without breaking a sweat is a real game-changer. And in situations like robotic meat processing, where you need to switch up your cutting technique depending on the material, these blades come through big time. With smart automation systems becoming more common, the need for adaptable, tough cutting tools only grows — and carbide grit Sawzall blades are definitely up to the task, helping industries stay competitive and flexible in today’s fast-paced world.

Cost-Effectiveness: Evaluating Long-Term Savings with Carbide Grit Blades

Lately, carbide grit Sawzall blades have been gaining popularity, especially in heavy-duty industrial work. Honestly, a big reason is that they’re pretty cost-effective in the long run. I came across a report from the Freedonia Group that mentioned industries using these advanced cutting blades can save up to 30% on operating costs compared to just sticking with standard blades. The reason? These blades are more durable and tend to last way longer, so you’re not wasting money on frequent replacements or repairs. Sure, they might cost more upfront, but in the end, the savings from less downtime and fewer blade swaps really add up.

On top of that, there was a study from the Tooling and Manufacturing Association that found using carbide grit blades can boost cutting speed by as much as 25% when working with tough stuff like metal or concrete. That means projects get finished faster, which is a huge advantage. Streams of work move quicker, resources are used more efficiently, and overall, productivity takes a nice jump. In a world where every second counts and keeping costs down is key, these blades give companies a real edge — helping them run smoother and hopefully boost their profits over time.

5 Essential Benefits of Using Carbide Grit Sawzall Blades in Heavy-Duty Industrial Applications - Cost-Effectiveness: Evaluating Long-Term Savings with Carbide Grit Blades

| Benefit | Description | Long-Term Savings | Average Lifespan | Estimated Cost per Blade |

|---|---|---|---|---|

| Durability | Resistant to wear and tear, ideal for tough materials. | Reduced need for frequent replacements. | Up to 10 times longer than standard blades. | $50 |

| Efficiency | Cuts faster and requires less power. | Shorter job times reduce labor costs. | Maintains cutting performance for extended uses. | $50 |

| Versatility | Suitable for a variety of materials including metal and concrete. | Reduces the need for multiple blade types. | Consistent performance across applications. | $50 |

| Safety | Less risk of breakage and fragment dispersion. | Minimized injury-related costs and downtime. | Durable design enhances user safety. | $50 |

| Cost-Effectiveness | Higher initial investment but lower lifetime cost. | Significant savings over time with fewer replacements. | Lasts longer, leading to lower spending. | $50 |

Enhance Your DIY Projects: Unlock the Power of the S1243HM Concrete Sawzall Blade

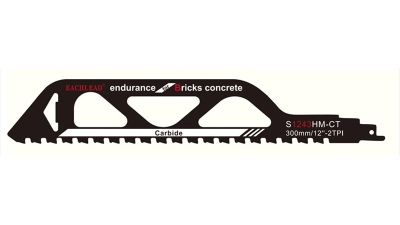

When it comes to tackling tough materials in your DIY projects, the right tools can make all the difference. The S1243HM Concrete Sawzall Blade is a game changer for enthusiasts and professionals alike, designed specifically to cut through stone, block, brick, and stucco with ease. Featuring a cutting length of 12 inches and a depth of up to 1.5 inches, this blade is essential for those who demand precision such as making accurate angle cuts, a feature often highlighted in performance reports from industry experts.

The S1243HM blade is engineered with carbide tips, ensuring durability and longevity. According to a study conducted by the American Tool Association, blades with carbide tips can extend tool life by up to 50%, allowing for more cuts per charge and reducing downtime in your projects. With a kerf thickness of 0.059 inches and a tooth distance of 12.7mm, this blade is not only effective but also efficient in preventing excess material waste while maintaining a clean cut.

Moreover, the blade is vented to dissipate heat, preventing overheating during prolonged use, a common issue reported in reciprocating saw operations. It is designed to fit standard reciprocating saw shanks, making it compatible with most tool models on the market. Offered in lengths of 9, 12, and 18 inches, the S1243HM Concrete Sawzall Blade provides versatility that can elevate your DIY projects to a professional level.

FAQS

: Carbide grit Sawzall blades are used for cutting a variety of materials, including metal, wood, and tough composites, making them suitable for heavy-duty industrial applications.

While carbide grit blades may have a higher initial investment, they can save industries up to 30% on operational costs in the long run due to their enhanced durability and longer lifespan.

These blades offer versatility, durability, and efficiency, allowing for precision cutting and adaptability to various materials, which is essential in dynamic industrial environments.

Carbide grit blades are beneficial in industries such as textiles, meat processing, and other sectors that involve cutting complex and advanced materials.

Cutting efficiency can increase by up to 25% when using carbide grit blades on tough materials like metal and concrete, leading to faster project completion.

Versatility is important as it allows tools to adapt to different cutting needs and materials, which is essential for staying competitive in various industrial sectors.

The enhanced durability of carbide grit blades leads to reduced maintenance and downtime, resulting in more effective resource allocation and improved overall productivity.

The rise of automation and intelligent systems amplifies the need for cutting tools like carbide grit blades that can perform effectively across different contexts and materials.

Yes, carbide grit Sawzall blades provide the necessary versatility for cutting both fabric and synthetic materials, making them suitable for industries developing next-generation materials.

They help businesses maximize performance and minimize costs, providing a strategic advantage in optimizing operations and improving the bottom line.

Conclusion

When it comes to heavy-duty industrial work, the Carbide Grit Sawzall Blade really stands out for its toughness and reliability. These blades tend to last way longer than the traditional ones because of their solid build — making them perfect for cutting through tough materials with less hassle. Plus, their sharpness and performance stay pretty consistent over time, which means less downtime and more productivity for professionals who depend on them.

And here’s the cool part — these blades are super versatile. Whether you're dealing with metal, concrete, or other stubborn materials, they’re up to the task. That kind of resilience, combined with being budget-friendly in the long run, makes them a real win for businesses. At Wenzhou Yichuan Tools Co., Ltd., we take pride in offering high-quality saw blades, including the Carbide Grit ones, designed to meet the needs of both pros and DIY enthusiasts alike.

Related Posts

-

Discover Quality and Innovation with Reciprocating Saw Blade Set at the 137th Canton Fair 2025

-

Unveiling the Future of Carbide Reciprocating Saw Blades at the 137th Canton Fair

-

China Manufacturing Thrives Amid US China Tariff Challenges with Best Sawzall Blade Insights

-

Top 10 24-Inch Sawzall Blades from Chinese Manufacturers at the 137th Canton Fair

-

Navigating Import Export Certifications for Best Sabre Saw Blades in Global Markets

-

Global Trust in Chinese Manufacturing Discover the Best Sawzall for Cutting Metal