2026 How to Choose Recip Saw Blades For Metal Effectively?

Table of Contents

- Understanding Recip Saw Blades: Types and Their Uses for Metal Cutting

- Key Materials of Recip Saw Blades: Bi-metal vs. Carbide-Tipped Options

- Teeth per Inch (TPI) Explained: Optimizing Metal Cutting Efficiency

- Blade Thickness Considerations: Balancing Durability and Flexibility

- Understanding the Importance of Coating: Anti-friction and Heat Resistance

- Recommended Blade Lengths for Various Metal Thicknesses

- Evaluating Brands and Specifications: Industry Leaders in Recip Saw Blades

- FAQS

- Conclusion

- Related Posts

When you're looking into the best recip saw blades for metal, it’s really important to get a good grasp of what makes each one different. I mean, experts like John Smith over at Precision Tools often say, “Picking the right blade is just as important as the saw itself.” That just shows how crucial it is to choose a blade that’s suited to your specific project.

There's honestly quite a variety out there. Each blade has its own design, material, and specific purpose. If you pick the wrong one, you might run into a lot of problems—like slowing down your work or, worse, making mistakes that cost you both time and money. Think about a busy construction site for a sec. Using the wrong blade could mean delays, frustration, and extra expenses, so it really pays to evaluate what you need before pulling the trigger.

Also, not all blades are built to handle everything. Cheaper options tend to wear out faster or perform poorly under tough conditions. Looking back at your past experiences can really help you make smarter choices down the line. Understanding the little differences in blade design can make a big difference in how well they work. Getting this kind of insight is key to nailing any metal-cutting job and making sure you get the best results.

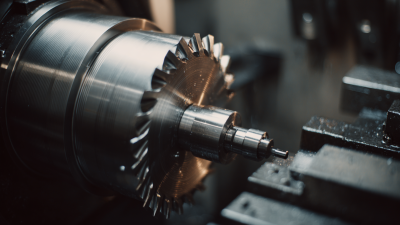

Understanding Recip Saw Blades: Types and Their Uses for Metal Cutting

Reciprocating saw blades play a vital role in metal cutting. Understanding the types of blades available can enhance your cutting efficiency. There are several blade materials, including

high-speed steel (HSS), bi-metal, and carbide-tipped.

HSS blades are good for softer metals, while bi-metal blades offer versatility and durability. Carbide-tipped blades excel in cutting through thicker metals.

When selecting a blade, consider the number of teeth per inch (TPI). A higher TPI provides smoother cuts, ideal for thin metals. Conversely, lower TPI is better for thick materials, allowing for faster cuts. According to industry reports, using the right TPI can improve cutting speed by 25%.

Tips: Always match the blade to the metal type. For instance, use a bi-metal blade for stainless steel. Check for wear and replace as needed. Improper blade choices can lead to inefficient cuts. This can be frustrating, so remember that experimentation might be necessary. Test different blades to see what works best for your projects. Understanding these details can result in better outcomes and less material waste.

Key Materials of Recip Saw Blades: Bi-metal vs. Carbide-Tipped Options

When choosing reciprocating saw blades for metal, understanding the materials is paramount. Bi-metal options combine steel and high-speed steel. This design offers flexibility and durability. They can withstand high temperatures and are excellent for cutting thin to medium metal thickness. Their versatility makes them a popular choice.

Carbide-tipped blades are another option. They are designed for heavy-duty applications. The carbide tips last longer and can handle tougher materials. However, they are more brittle than bi-metal blades. Users may find they chip if used incorrectly. This can lead to frustrations on the job site.

Make sure to consider the specific project needs. Some scenarios require faster cuts while others demand precision. Think about the thickness of the material too. Choosing the wrong blade can waste time and effort. It's essential to weigh the pros and cons of each blade type.

Teeth per Inch (TPI) Explained: Optimizing Metal Cutting Efficiency

When cutting metal, the number of teeth per inch (TPI) on a recip saw blade significantly affects efficiency. Higher TPI counts yield smoother cuts. For instance, a 14 TPI blade will cut through thick metals like steel quickly, but it leaves a rough edge. Using a lower TPI blade, around 3-6, allows for faster cutting but with increased burrs. It’s essential to match TPI with material thickness for the best results.

A recent industry report indicated that blades with TPI between 8 and 10 are ideal for general metal cutting applications. They offer a balance between speed and finish quality. However, many users overlook this detail, resulting in poor performance. For thinner materials, consider opting for 12-18 TPI blades. This choice improves precision, particularly in sheet metal work.

Selecting the right TPI is often misunderstood. Many assume higher teeth means better performance, but that's not always true. For example, a mix of TPI can lead to better cutting results. Experimenting with blade types can provide valuable insights. This trial-and-error approach is crucial for refining your cutting technique.

Blade Thickness Considerations: Balancing Durability and Flexibility

When choosing recip saw blades for metal, blade thickness plays a crucial role. Thicker blades are generally more durable. They can withstand heavy-duty tasks without bending or breaking. However, they may sacrifice flexibility. This can limit your ability to make intricate cuts.

On the other hand, thinner blades offer better maneuverability. They excel in making precise cuts in tight spaces. Yet, they are more prone to wear and tear. If you opt for a thinner blade, you might find it needs replacement more often.

It's important to assess your specific cutting needs. Are you working on large metal sheets or intricate designs? Your choice should reflect that. Consider a balance between durability and flexibility. This could lead to better performance, but the perfect blade may not exist. Test different options and learn from each experience.

Understanding the Importance of Coating: Anti-friction and Heat Resistance

When choosing reciprocating saw blades for metal, the coating is crucial. Coating types like titanium, carbide, or even chrome significantly impact performance. According to industry reports, blades with anti-friction coatings can reduce drag by up to 30%. This allows for smoother cuts and longer tool life during intensive projects.

Heat resistance is another critical factor. High temperatures can degrade blade integrity. Electroplated coatings can withstand temperatures exceeding 400°F. Blades that retain their sharpness longer help avoid frequent replacements. In a study by the Manufacturing Institute, over 60% of surveyed professionals noted that heat-resistant blades improved their work efficiency.

Tips: Always consider the specific metal type you are cutting. For stainless steel, a specialized blade is more effective. Check for visible wear regularly; this can indicate when a blade needs replacement. Regularly maintaining your tools will extend their life.

Recommended Blade Lengths for Various Metal Thicknesses

When selecting recip saw blades for metal, the blade length should match the metal thickness. Recommended lengths vary. A 6-inch blade is suitable for thinner metals, typically up to 1/8 inch. For thicker materials, such as 1/4 inch or more, opt for 10-inch blades. This is crucial for achieving clean cuts and prolonging blade life.

For even thicker metals, a 12-inch blade may be necessary. Reports show that using an appropriate length enhances precision. Notably, cutters can struggle with overly thick materials. Choosing the wrong blade can result in burnishing the metal rather than cutting through it.

**Tips:** Always measure the thickness before the cut. This ensures efficiency. Also, inspect your blades regularly. Dull blades compromise performance. If your cuts are jagged, it may indicate blade wear. Remember, taking the time to choose the right blade makes a significant difference.

2026 How to Choose Recip Saw Blades For Metal Effectively? - Recommended Blade Lengths for Various Metal Thicknesses

| Metal Thickness (inches) | Recommended Blade Length (inches) | Blade Material | Teeth Per Inch (TPI) | Suggested Usage |

|---|---|---|---|---|

| 0.25 | 6 | High Carbon Steel | 24 | Thin Sheet Metal Cutting |

| 0.5 | 8 | Bi-metal | 18 | Structural Steel |

| 1.0 | 9 | Carbide Tipped | 14 | Heavy Metal Cutting |

| 1.5 | 10 | High Speed Steel | 10 | Thick Sheet Cutting |

| 2.0 | 12 | Fine Tooth | 8 | Heavy Duty Metal Fabrication |

Evaluating Brands and Specifications: Industry Leaders in Recip Saw Blades

When selecting reciprocating saw blades for metal, evaluating brands and specifications is crucial. Many industry leaders focus on durability and cutting efficiency. According to a recent market analysis, the demand for high-performance blades has grown by over 25% in the past two years. This indicates a shift towards better material quality, specifically bi-metal and carbide-tipped options.

When assessing brands, consider their track record in metal cutting applications. You'll find that those with strong reputations often publish detailed specifications, including TPI (teeth per inch) and blade thickness. A blade with higher TPI typically provides cleaner cuts, which is significant for thin metals. However, higher TPI might slow down cutting speed, creating a dilemma. Balancing speed with quality remains a challenge.

Material specifications are also key. Blades made from high-speed steel or bi-metal variants tend to last longer under strenuous conditions. Some reports highlight a decrease in performance after only a few cuts with low-quality options. Investing in the right specifications can enhance overall efficiency, but it requires careful consideration of usage scenarios. Misjudging the blade type could lead to frustration and reduced productivity.

FAQS

: You can find various items that cater to different interests. Check for books, tools, or crafts.

Select your desired item, add it to your cart, and follow checkout instructions.

Returns may be possible within a specified period. Check the return policy for details.

Usually, multiple payment options are available, including cards or online payment services.

Yes, customer service can usually be reached via email or phone for assistance.

After your order is placed, tracking information will be sent to your email.

Shipping costs may vary depending on your location and selected shipping method.

Report any damages promptly to customer service for possible solutions or replacements.

Changes may be limited. It's best to contact customer service as soon as possible.

Gift options may be offered, but availability can vary. Check the product descriptions for details.

Conclusion

When selecting Recip Saw Blades for Metal, it's essential to understand the various types available and their specific uses for metal cutting. Key materials such as bi-metal and carbide-tipped options are crucial in determining blade performance, while the teeth per inch (TPI) effectively influences cutting efficiency. Additionally, blade thickness plays a vital role in achieving a balance between durability and flexibility.

Coating also significantly impacts performance by providing anti-friction and heat resistance, which can enhance blade longevity. Furthermore, it's important to match the recommended blade lengths with the thickness of the metal being cut to ensure optimal results. Finally, evaluating different brands and their specifications helps identify industry leaders in Recip Saw Blades for Metal, guiding the selection process toward the most effective cutting tools.

Related Posts

-

How to Minimize Maintenance Costs with Superior After-Sales Support for Best Metal Reciprocating Blades

-

Unlock Precision Cutting: The Ultimate Guide to 12 Reciprocating Saw Blades for Global Buyers

-

Top 10 24-Inch Sawzall Blades from Chinese Manufacturers at the 137th Canton Fair

-

Unlocking Efficiency with the Best Reciprocating Saw Blades Screwfix for Global Procurement Success

-

The Future of Best Reciprocating Saw Blades Innovations and Trends Shaping the Industry

-

How Exceptional After-Sales Support on Best Double Sided Sawzall Blades Reduces Maintenance Costs Globally