What is the Impact of Metal Cutting Sawzall Blades on Industrial Efficiency?

Table of Contents

- The Role of Metal Cutting Sawzall Blades in Enhancing Production Rates

- Comparative Analysis: Sawzall Blades vs. Traditional Cutting Tools in Efficiency

- Understanding Blade Material Composition and Its Impact on Cutting Performance

- Case Studies: Real-World Impact of Efficient Blades on Industrial Workflow

- Maximizing Lifespan of Metal Cutting Sawzall Blades for Cost Savings

- Key Metrics: Measuring Productivity Improvements with Advanced Blade Technologies

- Maximize Your Cutting Power: Why T118B Cheap Bulk Sawzall Blades Are Essential for Every DIY Enthusiast

- FAQS

- Conclusion

- Related Posts

In today’s fast-changing industrial world, staying efficient really makes or breaks success. One thing that often gets overlooked is how much Metal Cutting Sawzall Blades can impact overall productivity. I came across a recent report from IBISWorld that projects the global market for manufacturing tools will hit around $50 billion by 2025—pretty huge! This just goes to show how important good cutting tools are these days. Wenzhou Yichuan Tools Co., Ltd., which has been around since 2003, really knows their stuff when it comes to making top-notch electric tool accessories—think advanced jigsaw blades and reciprocating saw blades, perfect for both pros and DIY fans. Picking the right Metal Cutting Sawzall Blade can seriously cut down your working time and boost the quality of your cuts, which in turn ramps up overall efficiency. As industries scramble to meet rising market demands, the performance of these blades ends up being a key factor in delivering top-notch results and getting the best bang for your buck.

The Role of Metal Cutting Sawzall Blades in Enhancing Production Rates

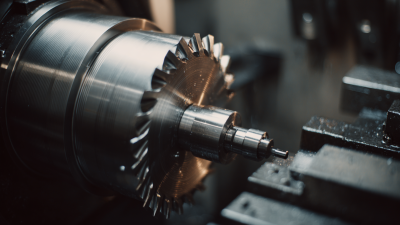

In today’s industrial world, how smoothly things run really depends a lot on the tools you’re using. Take metal cutting Sawzall blades, for example—they’re game changers when it comes to speeding up production because they cut faster without sacrificing precision. Thanks to new tech in coating processes, these blades last longer and perform better, making sure everything keeps running smoothly and efficiently. That’s especially important in industries like construction and manufacturing, where every second counts and accuracy is key.

The demand for metal cutting tools isn’t slowing down either. Market forecasts say it’s gonna hit a jaw-dropping US$ 141 billion pretty soon. One big driver of this growth? The rising popularity of saw blades. Experts expect sales to jump from about USD 16.8 billion in 2025 to a massive USD 26.4 billion by 2035. Companies like Wenzhou Yichuan Tools Co., Ltd. are out there working hard to provide top-notch electric tool accessories, including advanced jigsaw and reciprocating saw blades, crafted for both pros and DIY folks. By continually making these blades better, industries can stay ahead of the curve and keep up with the ever-growing need for faster, more efficient tools.

Comparative Analysis: Sawzall Blades vs. Traditional Cutting Tools in Efficiency

When you're trying to figure out which tools to use for industrial work, the choice between

Sawzall blades and traditional cutting tools really can make a big difference.

Sawzall blades, also known as reciprocating saw blades,

are all about speed and versatility. They can handle cutting through a variety of materials—metal,

wood, plastic—making them super handy in fast-paced work environments.

Unlike old-school tools that often need a different blade for each material, these blades make things

simpler, so you spend less time switching tools and more time getting the job done.

Now, if we compare them to traditional tools,

those usually shine when it comes to precision work. They’re great when you need clean,

detailed cuts. But, honestly, they can be a bit slow and less flexible when it comes to different

kinds of cuts. Sawzall blades, on the other hand, are perfect for rough cuts and demolition jobs—think

breaking down walls or doing quick, heavy-duty work. Because you can move quickly between tasks

without swapping out equipment, you end up doing more in less time, which is a big win on the

factory floor or at construction sites.

So, while traditional tools definitely have their moments—especially when you need that fine,

exact work—the efficiency and flexibility of

Sawzall blades are pretty hard to ignore, especially when speed really matters in your work environment.

Understanding Blade Material Composition and Its Impact on Cutting Performance

When it comes to metal cutting with Sawzall blades, what they're made of really matters for how well they perform and, in the end, how efficient your work gets. Usually, you'll find blades crafted from different materials like high-speed steel (HSS), bi-metal, or carbide-tipped options. For lighter jobs, high-speed steel blades work pretty well—they do the trick without breaking the bank. Then there's bi-metal blades, which are kind of the sweet spot—they mix HSS with softer steel, giving you a nice combo of durability and flexibility, making them suitable for a bunch of different cutting tasks. On the heavy-duty side, carbide-tipped blades are the real heavy hitters—they're designed to chew through tough metals and composites without much fuss.

Picking the right blade really boils down to understanding what you’re planning to cut. The material of the blade doesn’t just influence how fast you can cut—it also affects how long the blade stays sharp and how often you need to replace or sharpen it. A good choice in blade material means less downtime and fewer maintenance worries since your blade will keep its edge longer, reducing wear and tear. Plus, when you have the right blade for the job, you’ll cut more efficiently, finish projects quicker, and actually get more done in the same amount of time. So, paying attention to what the blade is made of and how that impacts performance can really help businesses stay productive and save money in the long run.

Case Studies: Real-World Impact of Efficient Blades on Industrial Workflow

You know, when it comes to boosting industrial workflows, using high-quality metal cutting Sawzall blades really makes a difference. I’ve seen cases where manufacturers who invest in better blades actually cut down their working times and get way more done overall. According to a recent report from Grand View Research, the global market for reciprocating saw blades is projected to hit around $560 million by 2027. That’s mainly because more industries are looking for tools that are both precise and durable. This trend just highlights how important it is for businesses to choose blades that can stand the test of time and get the job done right.

Here at Wenzhou Yichuan Tools Co., Ltd., we’ve been around since 2003, and we’re all about making top-notch reciprocating saw blades that meet the tough needs of professionals. Our blades are built with advanced materials to last longer and perform better—crucial for keeping things running smoothly and efficiently. From what we’ve seen, companies that use our Yichuan blades often cut their work times by up to 20%. That’s a huge savings, not to mention the boost in productivity. Plus, our blades last longer and need fewer replacements, so industries can focus more on what they do best—getting the job done without fussing over tools.

Maximizing Lifespan of Metal Cutting Sawzall Blades for Cost Savings

When you're trying to make those metal-cutting Sawzall blades last as long as possible, picking the right materials and techniques is super important—really, you can’t underestimate it. Lately, there’ve been some cool breakthroughs in materials, like tougher polymers and stronger metals, which has got a lot of industries rethinking how they approach their cutting tools. These new innovations make blades more durable and perform better, so you get cleaner cuts and don’t have to replace them as often. Honestly, investing in quality blades might cost a bit more upfront, but in the long run, it’s a total game-changer because it keeps your metal cutting smooth and saves you money.

Oh, and don’t forget—taking good care of your blades is key too. Regular cleaning and handling them gently can really help prevent early wear and tear. Also, it’s pretty important to know what type of metal you’re working with. Using blades optimized for specific materials can make your cuts easier and cut down on the stress on your tools. And hey, if you see sales on high-performance blades or cutting tools, don’t hesitate to grab those deals—sometimes those discounts can help you save now, but also make your work more efficient down the line. All these little tips add up to a more effective and cost-smart way to handle your metal cutting projects.

Key Metrics: Measuring Productivity Improvements with Advanced Blade Technologies

The advancements in metal cutting Sawzall blades are really making a big difference when it comes to industrial efficiency. You know, by paying attention to important stuff like how fast they cut, how long the blades last, and how versatile they are with different materials, manufacturers can really leverage new blade tech to make work smoother. For example, top-quality reciprocating saw blades are designed to cut faster and with less vibration, which means workers can get more done without sacrificing safety. Honestly, all these improvements don't just speed things up—they also make cutting tasks a lot more effective overall.

Wenzhou Yichuan Tools Co., Ltd., started back in 2003, and we’ve been leading the way in making these high-quality tools. We put a lot of effort into designing jigsaw and reciprocating saw blades that fit the needs of both pros and DIY folks. We’re always pushing ourselves to innovate and use the latest manufacturing techniques so that our blades can handle a wide range of jobs. As industries keep relying more and more on efficient cutting solutions, having the right blades becomes more crucial than ever. It’s really changing the game in how workflows are optimized and how productivity is judged.

Maximize Your Cutting Power: Why T118B Cheap Bulk Sawzall Blades Are Essential for Every DIY Enthusiast

When it comes to DIY projects, having the right tools can make all the difference in achieving clean cuts and efficient work. The T118B Cheap Bulk Sawzall Blades are a game-changer for enthusiasts looking to maximize their cutting power. These 3-inch, 14-tooth jig saw blades are designed with Bosch-style tang shanks, which not only provide a secure fit in your jigsaw but also eliminate the common weakness found in universal mounting blades—the set screw mounting hole, which is often a breaking point.

These blades are essential for anyone looking to tackle a variety of materials with precision and ease. Whether you're cutting through wood, plastic, or even metal, the superior design of the T118B blades ensures that you can trust their durability and performance. DIY enthusiasts can benefit from having a bulk supply of these blades on hand, ready to tackle any cutting challenge that arises, without the worry of frequent replacements.

With the T118B blades, you can confidently take on bigger projects, knowing that you’re equipped with reliable tools that enhance your cutting efficiency. Experience the difference of having blades that truly stand up to the demands of your DIY endeavors, and watch your projects come to life with greater skill and satisfaction.

FAQS

: Metal cutting Sawzall blades are used to enhance production rates by significantly reducing cutting times while maintaining precision, essential for sectors like construction and manufacturing.

Advancements in tool coating technologies improve the lifespan and performance of metal cutting blades, allowing for smoother and faster operations.

The metal cutting tools market is expected to reach US$ 141.09 billion, with the saw blades segment projected to increase from USD 16.8 billion in 2025 to USD 26.4 billion by 2035.

Manufacturers who invest in superior blades often experience reduced cutting times and improved overall productivity, leading to significant operational gains.

The global reciprocating saw blade market is expected to reach $560 million by 2027 due to the increasing demand for efficient tools in various industrial applications.

Companies using Yichuan blades achieve up to a 20% reduction in cutting time, leading to cost savings and enhanced operational performance.

Durable blades reduce the frequency of replacements, which allows industries to focus on their core activities and improves overall efficiency.

Wenzhou Yichuan Tools Co., Ltd. is a company established in 2003 that specializes in producing premium reciprocating saw blades designed for professional use, focusing on advanced materials for optimal performance.

Precision is critical in metal cutting tools as it directly impacts the quality of the cut and the overall effectiveness of the manufacturing process.

Sectors like construction and manufacturing benefit most from advanced Sawzall blades due to their need for speed and accuracy in cutting operations.

Conclusion

In today’s industrial world, how smoothly things run really depends a lot on the tools we use—especially the Metal Cutting Sawzall Blades. These blades can speed things up and give you cleaner, more accurate cuts than your standard tools. If you compare them side-by-side, you’ll see that while traditional methods might get the job done sometimes, the smarter design and better materials of these blades actually make a big difference. They help businesses boost their workflow and get more done in less time.

At Wenzhou Yichuan Tools Co., Ltd., we’ve been focusing on quality electric tool accessories since 2003, and we totally get how crucial these blades are in the industrial scene. We’ve done some case studies to show real-world results—like how much more you can get out of your tools when you use efficient blades—and also shared tips on how to make those blades last longer, saving you some cash. Overall, switching to these advanced Metal Cutting Sawzall Blades is pretty much a no-brainer if you want to level up your productivity and efficiency.

Related Posts

-

Unleashing the Power of Chinese Manufacturing with Top Tier Cast Iron Cutting Blades

-

Top Strategies for Choosing the Best Fire Rescue Sawzall Blades for Maximum Efficiency

-

5 Essential Tips for Choosing the Best Recip Saw Blades for Metal

-

How to Minimize Maintenance Costs with Superior After-Sales Support for Best Metal Reciprocating Blades

-

The Future of Innovative Fire And Rescue Reciprocating Saw Blades

-

The Ultimate Guide to Choosing the Right 16 Inch Reciprocating Saw Blade for Your Projects