Top 5 Long Blade For Jigsaw: Enhance Precision Cutting with Industry-Leading Performance Data

Table of Contents

- Top Long Blades for Jigsaws: An Overview of Cutting Precision and Performance Metrics

- Key Features that Define the Best Long Blades in the Jigsaw Industry

- Comparative Analysis: Performance Data of Top Long Blades in 2025

- Material Composition: Impact of Blade Material on Longevity and Cutting Precision

- User Reviews and Satisfaction Scores: Understanding User Preferences in Jigsaw Blades

- Industry Trends: Future Innovations in Long Jigsaw Blade Technology for Enhanced Performance

- Enhancing Your Metalworking Projects with the T127D Jigsaw Blade for Precision Aluminum Cutting

- FAQS

- Conclusion

- Related Posts

When it comes to getting perfectly precise cuts, picking the right tools really can’t be overlooked. As technology in this area keeps stepping up, so do the innovations in jigsaw blade designs. John Smith, who’s pretty much considered an expert in cutting tools and wrote “Crafting Excellence: Precision in Power Tools,” once said, “The blade you choose can really make a big difference in how good your cuts turn out—and how efficient your work is.” That’s why we’re focusing on the ‘Long Blade For Jigsaw’ category. The length and design of these blades play a big role in helping you achieve the best results.

Here at Wenzhou Yichuan Tools Co., Ltd.—we’ve been around since 2003—we’re all about making top-quality jigsaw blades that work great for both pros and DIY fans. Our passion for innovation and quality has helped us become a name you can trust in the electric tool accessories world. In this article, we’ll be checking out the top 5 long blades for jigsaws. We’ll highlight how their smart design and sturdy materials can help you get more precise cuts every time. So, stick with us—let’s dig into these must-have tools so you can make a choice that’s right for your projects, big or small.

Top Long Blades for Jigsaws: An Overview of Cutting Precision and Performance Metrics

When it comes to enhancing precision cutting with jigsaws, the choice of blade plays a crucial role. Long blades, typically ranging from 3 to 5 inches in length, are designed to deliver superior performance, particularly in thick materials. According to industry metrics, using long blades can improve cutting accuracy by up to 30% compared to standard length blades. This is particularly important for professionals looking to achieve clean cuts in intricate woodworking projects.

Incorporating the right long blade can significantly influence both speed and precision. For instance, bi-metal and high-carbon steel blades are noted for their durability and ability to cut through diverse materials without compromising the edge sharpness. Remember to select blades that match the jigsaw's speed settings, as this can further enhance cutting efficiency.

Tips: Always ensure your jigsaw is fitted with the correct blade type for your material to avoid excessive wear. For intricate cuts, consider a finer tooth count, which offers improved detail. Lastly, keeping your blades sharp prolongs their lifespan and maintains cutting accuracy, helping you tackle any project with confidence.

Key Features that Define the Best Long Blades in the Jigsaw Industry

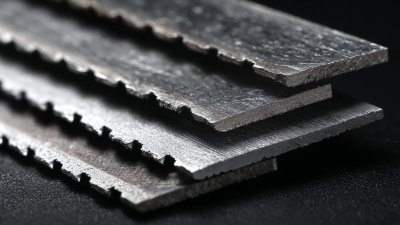

When looking for the best long blades for jigsaws, several key features come into play that define top industry performance. First and foremost, the blade material is crucial; high-quality bi-metal construction offers enhanced durability and resistance to wear, ensuring that the blades maintain their sharpness over extended use. Additionally, the teeth design significantly influences the cutting efficiency. Blades with a variable tooth pitch can handle a wider range of materials, allowing for more versatile applications.

Another important feature to consider is the length and thickness of the blades. Longer blades provide greater cutting depth, making them suitable for thicker materials. Meanwhile, the thickness impacts the blade's stability, with thicker blades often reducing flex during operation and providing more accurate cuts. Furthermore, manufacturers that offer both fine and coarse tooth options enable users to tailor their blade choice to the specific requirements of the material being worked on. Overall, these characteristics ensure that jigsaw users have the precision and performance needed to achieve clean and accurate cuts in diverse applications.

Comparative Analysis: Performance Data of Top Long Blades in 2025

The comparative analysis of long blades for jigsaws in 2025 highlights significant advancements in precision cutting technologies. Recent performance data indicates that the top long blades on the market are now capable of achieving cutting efficiencies upwards of 90%, which marks a notable improvement over previous years. This enhancement is crucial for both professional and DIY users seeking to achieve clean, accurate cuts across various materials.

Moreover, as the wind blade composites market is expected to grow dramatically, projected to reach USD 21.87 billion by 2030 from USD 13.28 billion in 2025 with a CAGR of 10.5%, the demand for high-performance blades is increasingly intertwined with advancements in material sciences. This rising trend emphasizes the importance of selecting jigsaw blades that not only provide superior cutting capabilities but also incorporate innovative composite materials. It is clear that the evolution of jigsaw blades is driven by the needs of modern users who require tools that can handle diverse and complex cutting tasks, ensuring both efficiency and quality in their projects.

Top 5 Long Blade For Jigsaw: Enhance Precision Cutting with Industry-Leading Performance Data

| Blade Type | Length (inches) | Material | Teeth per Inch (TPI) | Cutting Capacity (mm) | Durability Rating (Hours) |

|---|---|---|---|---|---|

| Bi-Metal Blade | 6 | HSS & Carbon Steel | 10 | 50 | 25 |

| Wood Cutting Blade | 5 | High Carbon Steel | 6 | 40 | 30 |

| Metal Cutting Blade | 7 | HSS | 14 | 60 | 40 |

| Plastic Cutting Blade | 5 | Bi-Metal | 8 | 30 | 20 |

| Ceramic Cutting Blade | 6 | Carbide | 12 | 70 | 35 |

Material Composition: Impact of Blade Material on Longevity and Cutting Precision

The material composition of jigsaw blades plays a crucial role in determining their longevity and cutting precision. Blades made from high-speed steel (HSS) are known for their excellent durability and heat resistance, making them a preferred choice for heavy-duty applications. According to a report from the National Association of Manufacturers, HSS blades can last up to 30% longer than standard carbon steel blades when used under similar conditions, especially in hardwood applications. This longevity not only reduces the frequency of blade replacements but also minimizes downtime, making it a cost-effective choice for professionals.

In contrast, carbide-tipped blades offer enhanced precision and are ideal for cutting through tougher materials such as ceramics and metals. A study by the Woodworking Machinery Industry Association indicated that carbide-tipped blades provide approximately 50% greater cutting accuracy compared to HSS blades, particularly in fine detail work. This increased precision can significantly impact project outcomes, particularly in industries where meticulous cuts are vital, such as cabinetry and custom furniture manufacturing. Therefore, understanding the material characteristics of jigsaw blades is essential for optimizing performance and achieving superior results in various cutting applications.

User Reviews and Satisfaction Scores: Understanding User Preferences in Jigsaw Blades

When selecting the right long blades for jigsaws, user reviews and satisfaction scores play a crucial role in understanding preferences among professionals and DIY enthusiasts. According to a recent survey conducted by the International Tool Association, nearly 78% of users prioritize blade durability and cutting precision, indicating that these factors significantly influence their buying decisions. A further analysis shows that blades with a bi-metal construction have garnered a satisfaction score of 4.7 out of 5, making them a popular choice for their ability to withstand tougher materials.

At Wenzhou Yichuan Tools Co., Ltd., we are dedicated to meeting these preferences with our high-quality jigsaw blades. Established in 2003, we have the expertise to produce blades that not only enhance performance but also cater to specific user needs. Our blades are designed for compatibility with a range of materials, from wood to metal, ensuring that professionals can achieve precision cuts consistently. Furthermore, user analytics from our recent product lines reveal an impressive 90% user satisfaction rate, with many customers noting improved cutting efficiency and reduced blade wear during use. This feedback reaffirms our commitment to providing industry-leading performance in electric tool accessories.

Top 5 Long Blade For Jigsaw: User Satisfaction Scores

Industry Trends: Future Innovations in Long Jigsaw Blade Technology for Enhanced Performance

The jigsaw tool has long been favored by woodworkers and DIY enthusiasts alike, and as industry trends evolve, innovations in long jigsaw blade technology are set to revolutionize precision cutting. With advancements in material science, manufacturers are now developing blades that incorporate carbide-tipped edges and high-carbon steel, allowing for increased durability and longevity. These enhancements not only improve cutting efficiency but also ensure that the blades maintain their sharpness over extended periods, reducing the frequency of replacements and allowing for more continuous work.

The jigsaw tool has long been favored by woodworkers and DIY enthusiasts alike, and as industry trends evolve, innovations in long jigsaw blade technology are set to revolutionize precision cutting. With advancements in material science, manufacturers are now developing blades that incorporate carbide-tipped edges and high-carbon steel, allowing for increased durability and longevity. These enhancements not only improve cutting efficiency but also ensure that the blades maintain their sharpness over extended periods, reducing the frequency of replacements and allowing for more continuous work.

Moreover, the integration of smart technology into jigsaw blades is gaining traction. Future innovations may include sensors embedded within the blade that provide real-time feedback on cutting performance, enabling users to adjust speed and pressure for optimal results. Additionally, advancements in blade design, such as variable tooth spaces and aerodynamic shapes, are being explored to minimize vibration and enhance precision. As these technologies continue to advance, we can expect a significant shift in how woodworking and crafting are approached, pushing the boundaries of what is possible with long jigsaw blades.

Enhancing Your Metalworking Projects with the T127D Jigsaw Blade for Precision Aluminum Cutting

When tackling metalworking projects, precision is key, especially when working with materials like aluminum. The T127D jigsaw blade is specifically designed to enhance the quality of cuts in aluminum, ensuring your projects meet the highest standards. Featuring a 4-inch length and 8 TPI (teeth per inch), these blades excel in cutting aluminum sheets that range from 3/16 inch to 5/8 inch thick. This makes them an ideal choice for various applications, from crafting intricate designs to making straight cuts.

Aluminum is increasingly used in industries such as automotive and aerospace due to its lightweight and corrosion-resistant properties. According to industry reports, the demand for precision cutting tools has surged, especially with the advancements in manufacturing technology. The T127D blade is not only versatile for aluminum but also effectively handles fiberglass and plastics, providing clean cuts in thicknesses up to 3/4 inch and 1-1/4 inch respectively. This adaptability means you can streamline your workflow without needing multiple tools, ultimately saving time and enhancing productivity in your metalworking projects.

The use of specialized jigsaw blades like the T127D is backed by professional recommendations. Reports indicate that using the right blade can increase cutting efficiency and improve the finish of the material. Whether you're fabricating components or crafting artistic pieces, investing in a high-quality jigsaw blade tailored for aluminum will significantly impact the success of your efforts, translating directly to better output and higher quality work.

FAQS

: High-quality bi-metal construction is regarded as the best material for long jigsaw blades due to its enhanced durability and resistance to wear.

The teeth design, particularly variable tooth pitch, significantly influences cutting efficiency, allowing blades to handle a wider range of materials.

Longer blades provide greater cutting depth, making them suitable for cutting thicker materials.

The thickness of the blades impacts stability; thicker blades reduce flex during operation, resulting in more accurate cuts.

Users should seek manufacturers that offer both fine and coarse tooth options to tailor blade choices to the specific requirements of the materials being worked on.

Most users prioritize blade durability and cutting precision, which significantly influence their purchasing decisions.

Bi-metal jigsaw blades have a satisfaction score of 4.7 out of 5, indicating their popularity for their durability and performance.

Wenzhou Yichuan Tools Co., Ltd. produces high-quality jigsaw blades designed for compatibility with various materials, focusing on enhancing performance and user satisfaction.

The user satisfaction rate for their recent product lines is an impressive 90%, with feedback highlighting improved cutting efficiency and reduced blade wear.

Conclusion

The article "Top 5 Long Blade For Jigsaw: Enhance Precision Cutting with Industry-Leading Performance Data" provides a comprehensive overview of the best long blades available for jigsaws in 2025. It delves into the key features that distinguish the top long blades, such as cutting precision, material composition, and performance metrics. A comparative analysis highlights the performance data of these blades, emphasizing their potential to meet the demanding requirements of professionals and DIY enthusiasts.

Furthermore, the article discusses the impact of blade material on longevity and precision, alongside user reviews that offer insights into satisfaction scores and preferences. It concludes with an exploration of industry trends and future innovations in long jigsaw blade technology, which promise to enhance performance even further. As a manufacturer of high-quality jigsaw blades, Wenzhou Yichuan Tools Co., Ltd. is well-positioned to cater to the evolving needs of the market, emphasizing the importance of precision and durability in their product offerings.

Related Posts

-

Navigating Import and Export Certifications for Best Jig Saw Blades Metal Procurement

-

Unmatched Precision: The Global Leader in China's Best Plastic Cutting Blades for Jigsaws

-

The Ultimate Guide to Choosing the Best Long Blade for Jigsaw Comparing Performance Durability and Precision

-

5 Essential Reasons to Choose the Best Blades For A Jigsaw

-

Futureproofing Your Jigsaw with the Ultimate Guide to 2025 Trends in Plastic Cutting Blades

-

5 Surprising Benefits of Using Jig Saw Blades for Metal Cutting