Top 10 Wood Blades for Jigsaws How to Choose the Best Blade for Your Project

Table of Contents

- Understanding Jigsaw Blades: Key Components and Features

- Types of Wood Blades: An Overview of Jigsaw Blade Choices

- Blade Tooth Count: How It Affects the Quality of Cuts

- Material Matters: Choosing the Right Blade Material for Wood

- Compatibility: Ensuring Your Blade Fits Your Jigsaw Model

- Project-Specific Suggestions: Selecting Blades for Varying Wood Types

- Maintenance Tips: Keeping Your Jigsaw Blades in Top Condition

- Revamping Your Woodworking Projects: Analyzing Makita NO.3 Jigsaw Blades' Performance Based on Recent Industry Reports

- FAQS

- Conclusion

- Related Posts

When you're dealing with jigsaws, picking the right wood blade is a pretty big deal if you want those cuts to come out nice and clean. Honestly, with so many blades out there, it can be kinda overwhelming trying to figure out which one actually fits your project best. Whether you’re just starting out with DIY stuff or you’ve been in the game for a while, knowing the ins and outs of different wood blades is super important if you want top-notch results.

In this little guide, I’ll walk you through the top 10 wood blades for jigsaws, pointing out what makes each one special and how they can help you out. From how the teeth are shaped to what they’re made of, each blade has its own perks for different kinds of wood and cutting styles. Once you get familiar with these options, you'll find yourself cutting more efficiently and getting better results in your woodworking projects. So, let’s dive into the world of jigsaw blades and help you make smarter choices for whatever you’re working on next!

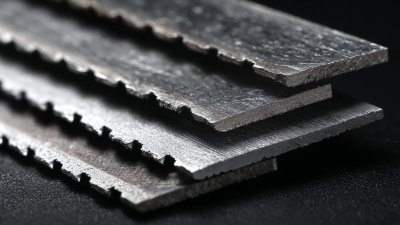

Understanding Jigsaw Blades: Key Components and Features

Understanding the components and features of jigsaw blades is essential for selecting the right blade for your woodworking project. Jigsaw blades vary primarily in their tooth configuration, material, and size, each tailored for specific cutting tasks. The tooth design typically influences the smoothness of the cut and the types of materials that can be effectively handled. For instance, fine-toothed blades are excellent for intricate cuts in wood, while more aggressive, larger-toothed blades excel in making quick, rough cuts.

Moreover, blade materials also play a crucial role in performance and durability. High-speed steel (HSS) blades are common for general cutting but may wear out faster than carbide-tipped options, which are designed to withstand higher levels of stress and provide prolonged performance, especially when cutting through harder materials. Understanding the length and width of the blades is also key; a longer blade allows for deeper cuts, while a wider blade provides additional stability.

Thus, knowing the essential components and features of jigsaw blades enables you to make informed decisions based on your specific project requirements.

Types of Wood Blades: An Overview of Jigsaw Blade Choices

When selecting the right jigsaw blades for woodworking projects, it's essential to understand the various types of wood blades available. Jigsaw blades can differ significantly in terms of tooth design, material, and application, which affects performance and the quality of the cut.

The primary types of wood blades include straight-cut, curved-cut, and scroll-cut blades—each tailored for specific woodworking tasks.

Straight-cut blades are ideal for making precise, clean cuts along straight lines. These blades typically have fine teeth that minimize splintering on wood edges.

Curved-cut blades excel at maneuvering around curves and can handle intricate patterns with ease, making them a favorite for detailed artwork and design work. For those who require intricate, detailed cutting, scroll-cut blades are the ultimate choice, featuring finer teeth that can navigate sharp turns and provide superior control in tight spaces.

Choosing the correct wood blade involves considering factors such as the thickness of the wood, the desired finish, and the complexity of the cut. A blade with fewer teeth per inch (TPI) removes material more quickly but may result in a rougher edge, while a higher TPI offers a smoother finish ideal for fine woodworking. Understanding these key types and characteristics ensures that woodworkers can select the best blade suited to their specific project needs.

Blade Tooth Count: How It Affects the Quality of Cuts

When selecting a wood blade for your jigsaw, understanding the impact of tooth count on cut quality is essential. The tooth count, typically measured in teeth per inch (TPI), directly influences the smoothness and precision of your cuts. According to industry standards, a lower TPI, usually between 3-6, is ideal for making quick and aggressive cuts in thicker materials, while a higher TPI ranging from 10-32 is better suited for finer cuts in softer woods or intricate patterns. As reported by the Association of Woodworking & Furniture Suppliers, a blade with higher tooth count results in less tear-out and splintering, thus enhancing the overall finish of the cut.

Moreover, research from the Woodworking Machinery Industry Association suggests that choosing the correct tooth geometry, in conjunction with TPI, can lead to a significant improvement in efficiency and blade life. For instance, blades designed with alternating top bevel (ATB) teeth and high TPI are especially effective for cross-cutting, offering cleaner edges. In contrast, blades featuring a skip-tooth design with lower TPI are better for faster cuts and thicker woods. Understanding these nuances equips DIY enthusiasts and professionals alike to make informed decisions, ensuring that their projects achieve the desired results with minimal rework.

Material Matters: Choosing the Right Blade Material for Wood

When selecting the best jigsaw blade for working with wood, the material of the blade plays a significant role in achieving optimal results. The two most common blade materials are high-carbon steel (HCS) and bi-metal (BIM) saw blades. HCS blades are known for their flexibility and are ideal for making curved cuts in softer woods. They are also more affordable, making them a great choice for casual DIY projects. However, for tougher hardwoods or extended usage, bi-metal blades, which combine HCS with high-speed steel, provide superior durability and longevity.

Tips for choosing the right blade material include considering the type of wood you’ll be cutting and the complexity of the cuts required. For intricate patterns or softer woods, opt for HCS blades, as they will provide smoother finishes. On the other hand, if your project involves cutting more rigid or thicker lumber, investing in bi-metal blades will save you time and effort in the long run.

Another aspect to consider is the tooth count and design. Blades with fewer teeth will cut faster and are suitable for rough cuts, while those with a higher tooth count are perfect for fine, detailed work. Always match the blade material and style to your specific woodworking project to ensure accuracy and efficiency. Your choice of blade not only affects the quality of your cut but can also influence the overall success of your woodworking endeavor.

Top 10 Wood Blades for Jigsaws: How to Choose the Best Blade for Your Project

| Blade Type | Teeth Count | Material | Ideal for | Cutting Speed |

|---|---|---|---|---|

| Fine Wood Blade | 10-12 | High-Speed Steel | Softwoods | Fast |

| Medium Wood Blade | 6-8 | Bi-metal | Hardwoods | Moderate |

| Coarse Wood Blade | 3-5 | Steel | Plywood | Slow |

| Plywood Blade | 12-14 | Carbide | Plywood Projects | Fast |

| Scroll Blade | 15-20 | High-Speed Steel | Intricate Cuts | Moderate |

| T-Shank Blade | 8-10 | Bi-metal | General Wood | Fast |

| Stubby Blade | 6-8 | High-Speed Steel | Compact Spaces | Slow |

| Finishing Blade | 10-12 | Carbide | Finish Work | Fast |

| Multi-Purpose Blade | 8-10 | Bi-metal | All Woods | Moderate |

| Specialty Blade | 10-14 | High-Speed Steel | Unique Cuts | Slow |

Compatibility: Ensuring Your Blade Fits Your Jigsaw Model

When selecting a wood blade for your jigsaw, one of the most crucial factors to consider is compatibility with your specific jigsaw model. Jigsaws come with different mounting systems, which can affect the fit of the blade. It is essential to check whether your jigsaw accepts T-shank or U-shank blades, as many modern jigsaws predominantly use T-shank blades due to their increased stability and ease of changing.

Additionally, the length and thickness of the blade can greatly impact both performance and safety. A blade that’s too long or too thick for your jigsaw may not function properly, leading to inefficient cuts or even damage to your tool. Before purchasing a blade, it's advisable to consult your jigsaw's manual or the manufacturer's specifications to ensure that you select a compatible blade that meets the project's demands.

This attention to compatibility will not only enhance your cutting experience but also ensure longevity and optimal performance from both your jigsaw and the blades used.

Project-Specific Suggestions: Selecting Blades for Varying Wood Types

When it comes to selecting the perfect jigsaw blade for a specific wood project, it's essential to consider the type of wood you are working with. Hardwoods, such as oak or walnut, require blades designed for precision cutting, typically featuring a higher tooth count. These fine-toothed blades minimize splintering and produce cleaner edges, which are crucial for projects that demand a smooth finish. On the other hand, softwoods like pine or cedar can be tackled with blades that have fewer teeth, allowing for faster cuts. These blades help to efficiently remove material without excessive heat buildup, which can cause damage to the wood.

Additionally, understanding the thickness of the wood is vital in blade selection. For thicker boards, blades with a longer length and sturdier design are beneficial, as they offer more stability during cutting. Conversely, for thinner pieces, a shorter blade may provide better maneuverability and control. Whether you're crafting delicate furniture pieces or building structural components, choosing the right jigsaw blade based on the wood type and thickness ensures optimal results and enhances the overall quality of your project. This thoughtful approach to blade selection not only improves efficiency but also elevates the craftsmanship of your woodworking endeavors.

Maintenance Tips: Keeping Your Jigsaw Blades in Top Condition

Maintaining your jigsaw blades is crucial for ensuring optimal performance and extending their lifespan. Regular maintenance not only saves you money but also enhances the quality of your cuts. To keep your blades in top condition, clean them after each use. Residue from wood and other materials can accumulate, leading to dullness and inefficient cutting. A simple solution is to use a soft cloth along with a suitable cleaner to wipe off any debris. For more stubborn buildup, soaking the blades in a mixture of water and mild detergent can be effective.

Another important maintenance tip is to regularly check the sharpness of your blades. Dull blades can cause rough edges and increased wear on your jigsaw. If you notice that your cuts are becoming less precise, it might be time to sharpen or replace your blades. Additionally, store your blades in a dry and organized manner to prevent accidental damage or rust. Using a protective case can help safeguard against environmental elements that may compromise their integrity.

Lastly, ensure that you use the correct blade type for your specific project. Different materials require different teeth configurationally—using the proper blade will not only make your work easier but also minimize wear and tear on the blades. By following these tips, you can keep your jigsaw blades performing at their best for all your woodworking projects.

Revamping Your Woodworking Projects: Analyzing Makita NO.3 Jigsaw Blades' Performance Based on Recent Industry Reports

When it comes to enhancing the performance of woodworking projects, the choice of jigsaw blades is crucial. Recent industry reports indicate that the type of blade can dramatically affect the precision and smoothness of cuts. Specifically, milled teeth jigsaw blades, such as those from reputable manufacturers, have been shown to outperform their counterparts in terms of both durability and cutting efficiency. The superior hardness and sharpness of milled teeth contribute to cleaner cuts and enhanced longevity, making them a preferred option for professional woodworkers.

Laboratory tests have demonstrated that jigsaw blades with milled teeth can reduce cutting time by up to 20% compared to stamped blades, enhancing productivity in busy workshops. Moreover, the customized options available allow craftsmen to select blades tailored to their specific project needs, ensuring optimal performance across a variety of materials. Industry analyses further reveal that demand for high-quality, customized jigsaw blades has surged, as woodworkers increasingly seek tools that offer both versatility and reliability, particularly in complex or intricate designs.

Free samples provided by manufacturers can also be an influential factor in decision-making, allowing craftsmen to assess the blade's performance firsthand. This hands-on approach not only fosters confidence in the product but also empowers woodworkers to make informed choices that align with their specific project requirements, ultimately leading to the successful execution of their woodworking ventures.

FAQS

: The primary types of jigsaw blades for woodworking include straight-cut, curved-cut, and scroll-cut blades. Each is designed for specific tasks, such as making clean cuts along straight lines, maneuvering around curves, or handling intricate patterns.

The tooth count affects how quickly material is removed and the finish of the cut. Blades with fewer teeth per inch (TPI) remove material more quickly but may result in a rougher edge, whereas higher TPI blades provide a smoother finish ideal for fine woodworking.

For hardwoods such as oak or walnut, it's best to use blades with a higher tooth count. These fine-toothed blades minimize splintering and result in cleaner edges, which are essential for projects requiring a smooth finish.

It's not advisable to use the same blade for all wood types. Softwoods can be cut with blades that have fewer teeth for faster cuts, while hardwoods require blades designed for precision with a higher tooth count.

The thickness of the wood is crucial in blade selection. Thicker boards require longer and sturdier blades for stability, while thinner pieces are better suited for shorter blades that provide improved maneuverability and control.

To maintain jigsaw blades and extend their lifespan, clean them after use, check their sharpness regularly, store them properly to prevent damage, and use the correct blade type for each project. Cleaning can involve wiping with a soft cloth or soaking in soapy water for stubborn buildup.

If you notice that your cuts are becoming less precise or result in rough edges, it may be an indication that your jigsaw blades are dull and need sharpening or replacement.

No, using a dull blade can lead to rough cuts and increased wear on your jigsaw, potentially causing damage to your workpiece. It’s important to ensure that blades are sharp for optimal performance.

Store your jigsaw blades in a dry and organized manner, ideally in a protective case, to prevent accidental damage and rust. Proper storage safeguards the blades from environmental elements.

Conclusion

Choosing the right wood blade for a jigsaw is essential for achieving high-quality cuts in various woodworking projects. Understanding the key components and features of jigsaw blades, including the types available, tooth count, and blade material, can significantly impact your results. Different wood blades are suited for different applications, so it's crucial to select one that matches the specific type of wood you're working with.

Additionally, compatibility between the blade and your jigsaw model is paramount to ensure optimal performance. Regular maintenance of your wood blade for jigsaw will also help prolong its lifespan and maintain cutting efficiency. By following these guidelines, you can confidently select the best wood blade for your jigsaw, tailored to your project needs.

Related Posts

-

Unmatched Precision: The Global Leader in China's Best Plastic Cutting Blades for Jigsaws

-

The Ultimate Guide to Choosing the Best Long Blade for Jigsaw Comparing Performance Durability and Precision

-

Navigating Import and Export Certifications for Best Jig Saw Blades Metal Procurement

-

5 Essential Reasons to Choose the Best Blades For A Jigsaw

-

Futureproofing Your Jigsaw with the Ultimate Guide to 2025 Trends in Plastic Cutting Blades

-

5 Surprising Benefits of Using Jig Saw Blades for Metal Cutting