Ever grabbed a wood reciprocating saw for a project, only to end up with splintered edges or uneven lines that ruin your work? You’re not alone. This versatile tool is a staple in workshops, job sites, and DIY garages, but mastering clean cuts takes more than just power—it’s about matching technique to wood type and tool setup. Let’s break down the pro tips to get smooth, precise results every time with your wood reciprocating saw.

Key Prep Step: Choose the Right Blade for Wood

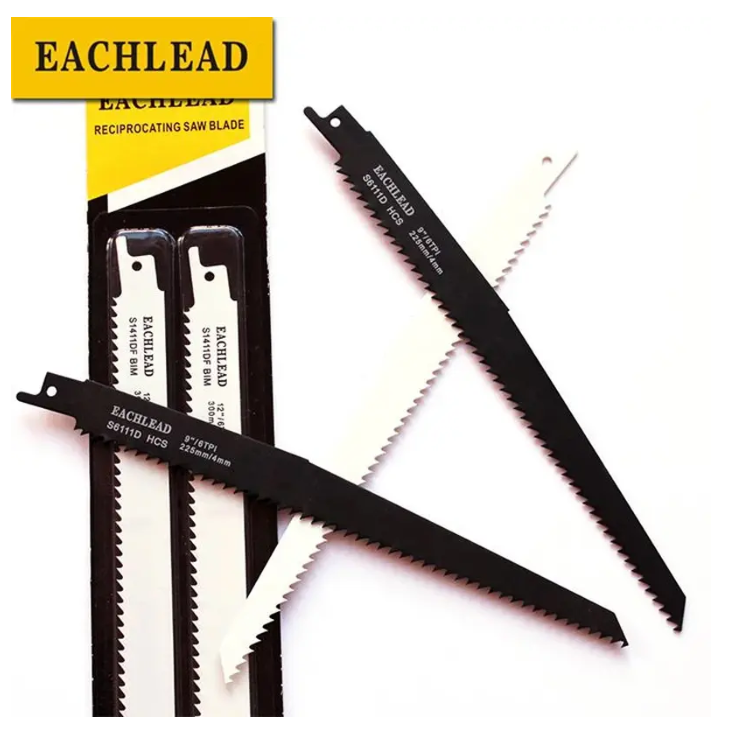

The biggest mistake DIYers and even pros make is using a one-size-fits-all blade. A wood reciprocating saw’s performance lives or dies by its blade, and matching it to your material is non-negotiable for clean cuts. Here’s how to pick wisely:

Teeth Per Inch (TPI): For softwoods like pine or cedar, opt for 30-40 TPI blades—fewer, larger teeth let you cut fast while preventing tear-out. Hardwoods (oak, walnut, mahogany) need 60-80 TPI blades; finer teeth reduce single-tooth load, avoiding jagged edges. Skip ultra-high TPI (10+) blades—they’re made for metal, not wood.

Tooth Style & Material: Alternate-tooth blades work best for hardwoods, as their offset design minimizes (splintering). For softwoods or lumber with knots, go for negative rake teeth—they’re more impact-resistant. Bi-metal blades are the industry standard; their HSS teeth bonded to an HCS body balance durability and sharpness, handling everything from framing lumber to finished boards.

Blade Length: Use a blade 2-3 inches longer than your material thickness. Shorter blades offer better control for precision cuts, while longer ones reach deep into thick stock without binding.

Pro Techniques for Clean Cuts

Even the best blade won’t save a sloppy technique. Follow these habits to keep your wood reciprocating saw on track and your cuts smooth:

Stabilize with the Saw Shoe

The adjustable shoe (or base) of your wood reciprocating saw is your secret weapon for stability. Press it firmly against the workpiece before starting—this reduces vibration, which causes splintering and wobbly lines. Tilt the shoe slightly so only the leading edge of the blade makes contact first; this eases the blade into the wood gently.

Match Speed to Wood Type

Most modern wood reciprocating saws have variable speed controls—use them. For hardwoods, slow down the reciprocating frequency (1500-2500 strokes per minute) and feed rate (no faster than 15m/min) to let the blade cut through dense fibers cleanly. Softwoods handle faster speeds (3000-4000 strokes per minute) and feeds (up to 25m/min), but don’t rush—speed kills precision.

Prevent Splintering with Simple Hacks

Splintering is the bane of clean wood cuts. For veneered boards, plywood, or finished lumber, apply painter’s tape along the cut line—cover both sides of the board. The tape holds wood fibers in place as the blade passes through. For solid hardwoods, score the cut line with a utility knife first; this creates a clean edge for the blade to follow.

Wood Reciprocating Saw: Industry Context & Limitations

In the woodworking industry, a wood reciprocating saw is prized for its versatility, not just precision. Unlike table saws or miter saws, it excels at tight spaces—think cutting joists in a crawlspace or trimming door frames in place—and cuts that other tools can’t tackle. It’s a workhorse in renovation, framing, and furniture repair, where adaptability matters more than batch-perfect cuts.

That said, it’s not a replacement for precision tools. For mass-produced cabinetry or fine woodworking, pros pair reciprocating saws with CNC models for complex cuts, or use them for rough cuts before finishing with a sander or planer. The key is understanding its role: a wood reciprocating saw is for solving tough cutting problems, and with the right tips, it can deliver shop-worthy results.

Troubleshooting Common Issues

Even with the right setup, issues pop up. Here’s how to fix them fast:

Burn Marks: Caused by friction from dull blades or blocked chips. Sharpen or replace the blade, and clear sawdust with a vacuum or compressed air. For resinous woods , wipe the blade with alcohol every 30 minutes to remove buildup.

Wobbly Cuts: Check the saw shoe—if it’s loose, tighten it. Ensure the blade is properly clamped; a loose blade vibrates. If the issue persists, inspect the blade for warping or the saw’s for wear.

Blade Binding: Don’t force the saw. Back it out slightly, clear chips, and adjust your feed rate. Binding often happens with dull blades or improper blade length—double-check both.

With these tips, your wood reciprocating saw will go from a demolition tool to a precision cutter. Remember: clean cuts start with preparation—choose the right blade, stabilize your work, and let the tool do the heavy lifting. Whether you’re a DIYer refinishing a deck or a pro on a job site, mastering these habits will elevate every wood project.

Post time: Jan-22-2026