Recip Saw Blades are the consumable cutting components designed for use with reciprocating saws, powerful tools known for their aggressive cutting action. The model S1111D represents a category of blades that balances cost-effectiveness with high-quality performance. These blades are engineered to transform the saw’s powerful back-and-forth motion into efficient material removal, making them indispensable for demolition, construction, and renovation tasks where speed and versatility are paramount.

The performance of these Recip Saw Blades is significantly enhanced by the features of modern reciprocating saws. Most contemporary saws offer variable speed control, adjustable through the trigger or a dial, allowing the user to match the blade’s cutting pace to the specific material. Furthermore, the orbital action setting available on many saws introduces a slightly elliptical path to the blade’s stroke. This motion aggressively pushes the blade into the workpiece on the cutting stroke, greatly increasing cutting speed in softer materials like wood.

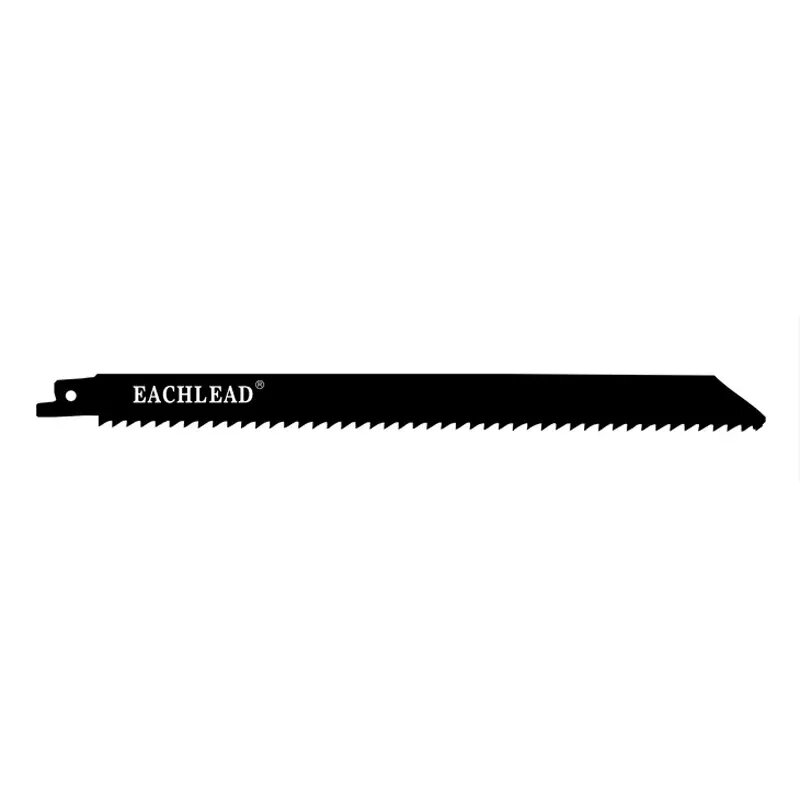

The design and construction of a Recip Saw Blades are critical to its application and durability. The S1111D type is typically manufactured from robust materials to withstand the high-impact nature of reciprocating cutting. Key attributes include the blade’s tooth design, which determines the cutting aggressiveness and finish, and its length, which dictates the maximum cutting depth. A secure mounting shank ensures the blade is firmly held in the saw’s clamp, preventing slippage during operation.

These blades are versatile and are utilized across a wide range of materials. They are commonly employed for cutting metal pipes, nails, and structural components, as well as for pruning trees and cutting wooden beams. The correct selection of a blade,considering factors like tooth-per-inch (TPI) and material composition,is crucial for achieving a clean cut, maximizing blade life, and ensuring operational safety.

The effectiveness of a reciprocating saw is directly dependent on the blade chosen for the task. Blades like the S1111D are fundamental to leveraging the full potential of the tool’s variable speed and orbital functions. By selecting the appropriate Recip Saw Blades for the specific material and application, users can achieve optimal cutting efficiency, control, and productivity in their work.

Post time: Oct-23-2025