When starting a woodworking project, choosing the right jigsaw blade for wood is crucial for success. A jigsaw is a versatile tool, but using the wrong blade can cause rough cuts, splintering, or even damage. This guide helps you select the perfect wood blade for jigsaw tasks, ensuring clean, safe, and efficient results every time. Let’s explore the key factors to consider based on your specific type of wood and the cut you need to make.

Understanding the Basics: Teeth Per Inch (TPI)

1.The most critical factor is TPI—teeth per inch.

- Low TPI (e.g., 6-10): Ideal for fast, rough cuts in thick wood or lumber. Fewer, larger teeth remove material quickly.

- High TPI (e.g., 10-20+): Best for slow, smooth cuts and fine details in plywood, hardwood, or when minimizing splintering. More teeth create a finer finish.

A Simple Blade Selection Guide for Common Wood Tasks

Match the blade to your material and desired cut for the best outcome:

1.For General Ripping & Crosscutting (2x4s, pine, softwood):

Use a: Standard Shank Wood Cutting Blade with 6-10 TPI.

Why: It’s durable and cuts fast. Look for a progressive tooth design blade for versatile use.

2.For Clean, Splinter-Free Cuts in Plywood or Laminates:

Use a: Reverse-Tooth (Downward-Cut) Blade with a higher TPI (10-12).

Why: The teeth cut on the downstroke, leaving a clean top surface. This is a top choice for finish carpentry.

3.For Intricate Curves and Detailed Shapes:

Use a: Narrow, Fine-Tooth Blade (often called a scrolling blade) with 10-20 TPI.

Why: The thin body allows for tight turns without binding.

4.For Fast, Aggressive Cutting in Thick Stock:

Use a: Coarse Tooth Blade (3-6 TPI) like a jigsaw blade for wood and nails or a bi-metal blade.

Why: Long gullets clear chips efficiently. A bi-metal construction offers flexibility and durability for tougher jobs.

Key Features of a Quality Wood Blade for Jigsaw

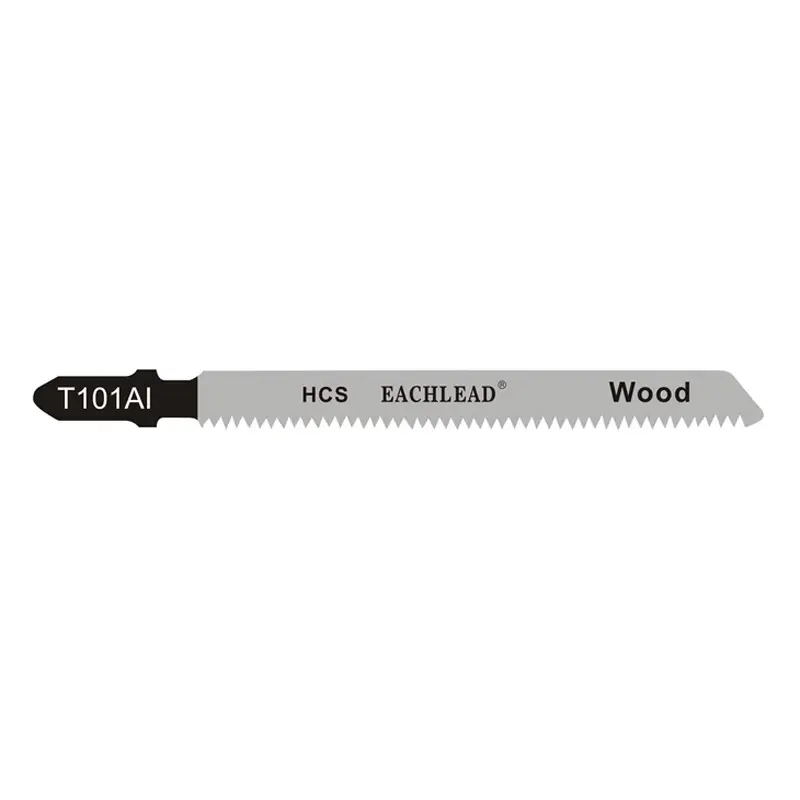

1.Material: High-carbon steel (HCS) is good for softer woods; bi-metal blades last much longer, especially in hardwoods.

2.Shank: Ensure it matches your tool—most are T-shank (tool-less change) or U-shank.

Tooth Grind: Look for precision-ground teeth for sharper, more consistent performance.

Pro Tips for Better Cuts

1.Face Side Down: For laminates or veneered wood, cut with the good face down. For solid wood, the good face should be up.

2.Use the Right Speed: Let the blade do the work. Use a slower speed for harder woods and metals.

3.Secure Your Workpiece: Always clamp it down firmly.

4.Blunt is Bad: A dull blade causes burn marks and rough cuts. Change it promptly.

Finding a Reliable Source for Your Blades

Whether you’re a DIY enthusiast or a professional, using reliable, purpose-made blades transforms your jigsaw into a precision tool. For those who demand consistent quality, YICHUAN TOOLS offers a comprehensive range of jigsaw blades for wood, from standard wood cutting blades to specialized reverse tooth and bi-metal options. Engineered for performance and durability, their blades are backed by major international certifications and are available through a global distributor network. For larger projects or workshop needs, their bulk purchasing options provide notable value without compromising on the precision required for clean wood cuts.

Final Cut

Choosing the right wood blade for jigsaw work comes down to three things: the type of wood, the thickness of the material, and the quality of finish you require. Start with a versatile down-cutting blade in the 10-14 TPI range for most tasks, and add specialized blades to your kit as your projects demand.

Post time: Dec-25-2025